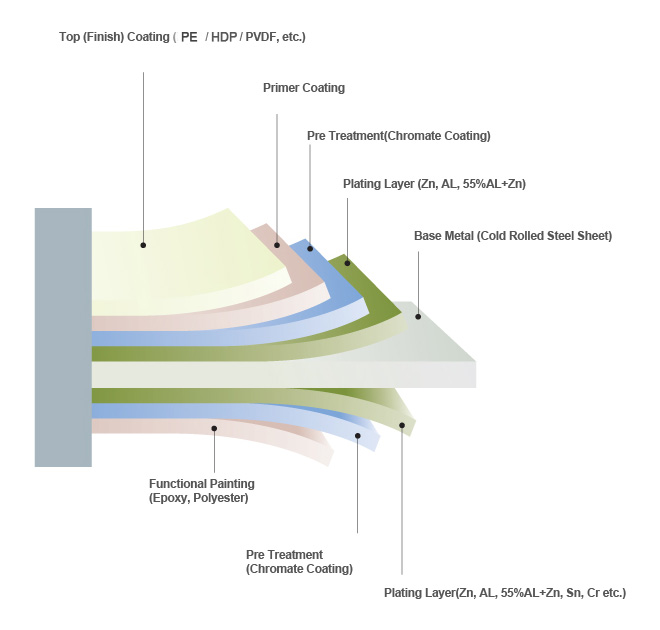

The prepainted steel sheet in coil is a product obtained by subjecting a hot-dipped galvanized steel sheet, and galvalume steel sheet, or an aluminum sheet to a surface chemical treatment (coating), followed by baking and curing.

1) PPGI is also known as prepainted galvanized steel coil and color coated steel coil, with a hot dip zinc coated steel sheet substrate.

2) PPGL is also known as prepainted galvalume steel coil, with a galvalume steel sheet as a substrate.

| Product name | Prepainted Galvanized Steel Coil |

| Material | DX51D |

| Zinc | 20-120g |

| Thickness | 0.13-0.8 mm |

| Width | 600-1250 mm |

| Color | all RAL color , as client’s request |

| Paint | top paint : 10-30mic back paint: 5-25 mic |

| Paints | PE, SMP, HDP, PVDF |

| T bend | |

| Pencil hardness | >2H |

| Coil ID | 508/610mm |

| Coil weight | 3-8tons |

| Surface | glossy and matt |

| Glossy | 30%-90% |

| Package | standard export package (Detailed picture is as follows) |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| HS code | 721070 |

| Country of origin | China |

| Business type | Supplier and manufacturer |

| Brand name | GNEE STEEL |

The prepaint galvanized steel coil prices keep changing, which is calculated based on raw material(Hot rolled sheet), width, thickness, paint, and zinc. Here is the only reference price, Please email us to get the precise price.

The decoiler machine unwinding, leveling, fixed-length, cut the prepainted galvanized steel coil into a flat PPGI sheet of the required length and width and is processed into a PPGI roofing sheet of various styles by a roll forming machine, such as corrugated steel sheet, wave tile, roman longtime profile.

Mechanical properties of PPGI(pre-painted galvanized) steel coil substrate.

| Grade | Yield Strength a,b MPa | tensile strength MPa | Elongation after breakingc A 80mm % not less than | r 90 not less than | n 90 not less than |

| DC51D+Z | - | 270~500 | 22 | - | - |

| DC52D+Z | 140~300 | 270~420 | 26 | - | - |

| DC53D+Z | 140~260 | 270~380 | 30 | - | - |

| DC54D+Z | 120~220 | 260~350 | 36 | 1.6 | 0.18 |

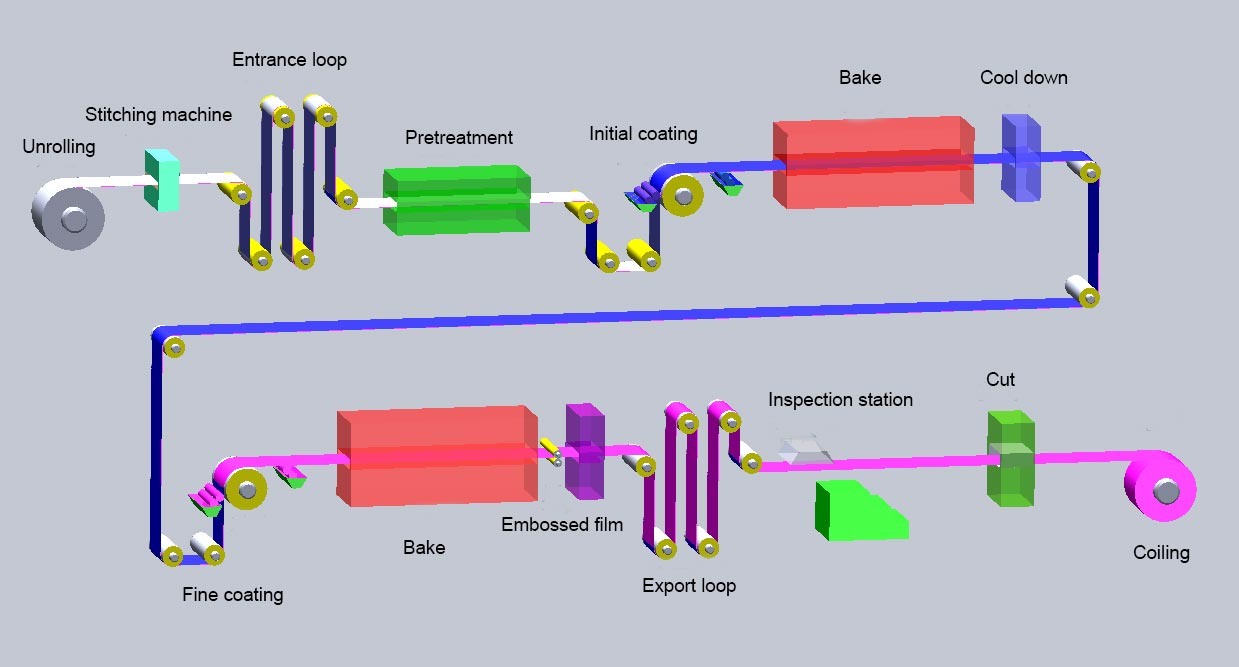

Unrolling → Stitching machine → Entrance loop → Pretreatment → Initial coating → Bake → Cool down → Fine coating → Bake → Embossed film → Export loop → Inspection station → Cut → Coiling

In the above process, if the cleaning degreasing process is not handled well, the adhesion of the primer of the color coated plate to the galvanized sheet is not good, and it is easy to cause the topcoat of the color coated steel coil to fall off during the press forming process.

The coating types currently used for PPGI/PPGL steel coil include PE, PVDF, SMP, acrylic, PVC, etc.

The PE-coated color-coated steel sheet is easy to be processed and formed because of its good adhesion, and the price is relatively cheap. But the other degree of UV resistance and chalking resistance is relatively low. PE color coated steel can be used for the roof of ordinary civil buildings.

SMP steel plate has better durability, and the cost is higher than the PE coating. Silicone is not as good as PE in terms of adhesion and processing formability to materials,

It is better than ordinary SMP coatings, and its outdoor weather resistance reaches 16 years. Its flexibility and weather resistance are higher.

PVC coating has nice anti-chemical and anti-water, and the coasting is relatively thick, which can well protect the substrate.

The PVC coating is rarely used because they pollute the environment.

PVDF coatings have great color retention and corrosion resistance. Among the PPGI sheet coating for construction, it is the highest grade.

The comprehensive performance is good, the price is expensive, and it is only used in specific fields (such as containers).

| Coating primer | Top paint coating | Service life(years) |

| 1) Epoxy primer, good adhesion, water resistance, alkali resistance, chemical corrosion resistance, poor single toughness. 2) Polyester primer, good adhesion, good flexibility, sensitive to humid environment, chemical resistance is not as good as epoxy primer. 3) Acrylic primer, good adhesion, good toughness and high pretreatment requirements. 4) polyurethane primer, chemical resistance, abrasion resistance, durability, toughness |

1) Polyester resin, good adhesion, molding and outdoor durability. | 8-10 |

| 2) Silicon Modified Polyester (SMP) | 10-15 | |

| 3) High weather resistant polyester (HDP) | 12-15 | |

| 4) Polyvinyl fluoride (PVC) | 12-15 | |

| 5) Polyvinylidene fluoride/fluorocarbon (PVDF) It has good formability and color retention, good outdoor durability and powder resistance, solvent resistance, limited color and high price. | 12-20 |

| Category | Hardness | Bend | Corrosion resistance | Weather resistance | Cost | Coating thickness requirements /um |

| Polyester | excellent | good | good | good | excellent | 20 |

| Acrylic | excellent | general | good | good | inferior | 20 |

| Silicon modified polyester | good | general | good | excellent | good | 20 |

| PVC sol | general | excellent | excellent | good | inferior | 200 |

| PVDF | general | excellent | excellent | excellent | inferior | 25 |

| HDP | good | excellent | good | excellent | good | 20 |

You need to consider when choosing a primer

1) Adhesion of primer and finish coating

2) Corrosion resistance of primer

For the back coating, if the color-coated steel sheet is a Single layer, Color coated steel with a back primer plus a back finish coating was selected.

The primer is of the same variety as the front, and a layer of light color (such as white) polyester is selected for the finish coating.

If the PPGI steel coil is used as a sandwich panel, a layer of epoxy resin with excellent adhesion and corrosion resistance is sufficient.

The front coating is larger than 20μm to prevent the intrusion of corrosive media. Due to the different anti-corrosion mechanisms of primer and finish coating, not only the total coating thickness should be guaranteed, but also the thickness of primer (>5μm) and finish coating (>15μm).

PVDF color coated steel coil requires a thicker coating. It provides a longer service life. The requirements for the backside paint coating depend on the application, and the sandwich panel only requires a layer of primer. The formed steel plate requires two coats. The thickness is at least greater than 10 μm.

The choice of coating color mainly considers the use of environment and market demand. The light color paint has a strong heat reflection ability, and the contrast between the coating and the original color is small, and the appearance is small. Dark colors will fade easily when exposed to ultraviolet light.

Different colors have different reflectivity to sunlight. The following table lists the reflectivity of different colors.

Also, there are 2 misunderstandings:

First, there are a large number of white primers. The purpose of using a white primer is to reduce the thickness of the finish coating so that the corrosion resistance becomes poor, and the 10micron finish coating is also very thin. Corrosion may occur in places such as cuts and bends within two years.

Second, color-coated steel plates for construction from different manufacturers and different batches in the same project. The colors seem to be the same during construction, but after several years of sunlight, serious color differences may occur. Even if the color coated steel from the same supplier, it is recommended to order the same project at one time.

The metallic coating of color coating for construction is hot-dip galvanized and galvalume. The greater the thickness of the metallic coating, the better the corrosion resistance.

The thickness of the metallic coating mainly affects the cut corrosion performance of the color-coated steel sheet, and the influencing factors include the finish coating, primer, substrate thickness, and metallic coating thickness.

The thickness of the substrate and the thickness of the metallic coating affect the notch corrosion. The thinner the substrate and the thicker the metallic coating, the better the corrosion resistance of the notch.

For buildings, the bearing weight (wind load, snow load) and the span of the building all depend on the strength of the steel plate. Divided into CQ, DQ, HSS, FH according to steel types.

Noted:

Generally, the PPGI coils for construction are rolled forming or sandwiched. Please use CQ steel.

The substrate of the prepainted steel coil has a cold-rolled substrate, hot-dipping galvanized substrate and, aluzinc substrate.

prepainted steel sheets produced from cold-rolled substrates have the processing properties of cold-rolled sheets.

If the coating is scratched, the cold-rolled substrate will be directly exposed and will quickly rust. It can only be used for temporary barriers that are not demanding. It has the lowest price and is not recommended for civil buildings.

In addition to the protective effect of zinc, the prepainted galvanized steel sheet also has coating protection, and the service life is longer than that of the hot-dipping galvanized steel sheet.

Hot-dipping galvalume steel (55% AI-Zn) is used as the prepainted galvalume steel coil substrate.

The corrosion resistance of hot-dipping galvalume steel sheets is 2 to 5 times that of hot-dipping galvanized steel sheets.

Noted:

The above three are the most common pre-painted steel coil substrates, To ensure longer service life. For building roofing applications, it is recommended to choose galvanized substrates and galvalume substrates.

The color difference of the paint itself;

The drying process;

Paint coating thickness;

Glossy of paint;

Choosing a prepainted steel coil needs to consider the natural environment, use environment, design life, and structural characteristics of the building to match the appropriate steel grade, specifications, Metallic coating, and coating.

The performance of color coated steel sheet mainly includes the mechanical properties of the material (tensile strength, yield strength, elongation), Metallic coating performance (Metallic coating type, thickness, and adhesion), and coating performance (coating species, color, gloss, durability, Processability, etc.)

The main consideration for the selection of color-coated steel sheets in different regions is the local wind and snow load and corrosive environment.

Non-ferrous metal smelters (zinc, copper, lead, etc.) are the most challenging service life of color coated steel.

The beauty and durability of civil buildings are the primary considerations for the prepainted steel sheet. Therefore, it is very important that the coating resists discoloration, pulverization, and the coating surface is complete and fine.