The position of pickling and neutralizing water equipment in hot-dip galvanizing production line

Intelligent hot-dip galvanizing production line is a kind of metal surface treatment process with high efficiency and environmental protection, in which the pickling and neutralizing water equipment is a crucial part of the production line.

This article will introduce the pickling neutralization water equipment in the intelligent hot-dip galvanizing production line location, role and related technology.

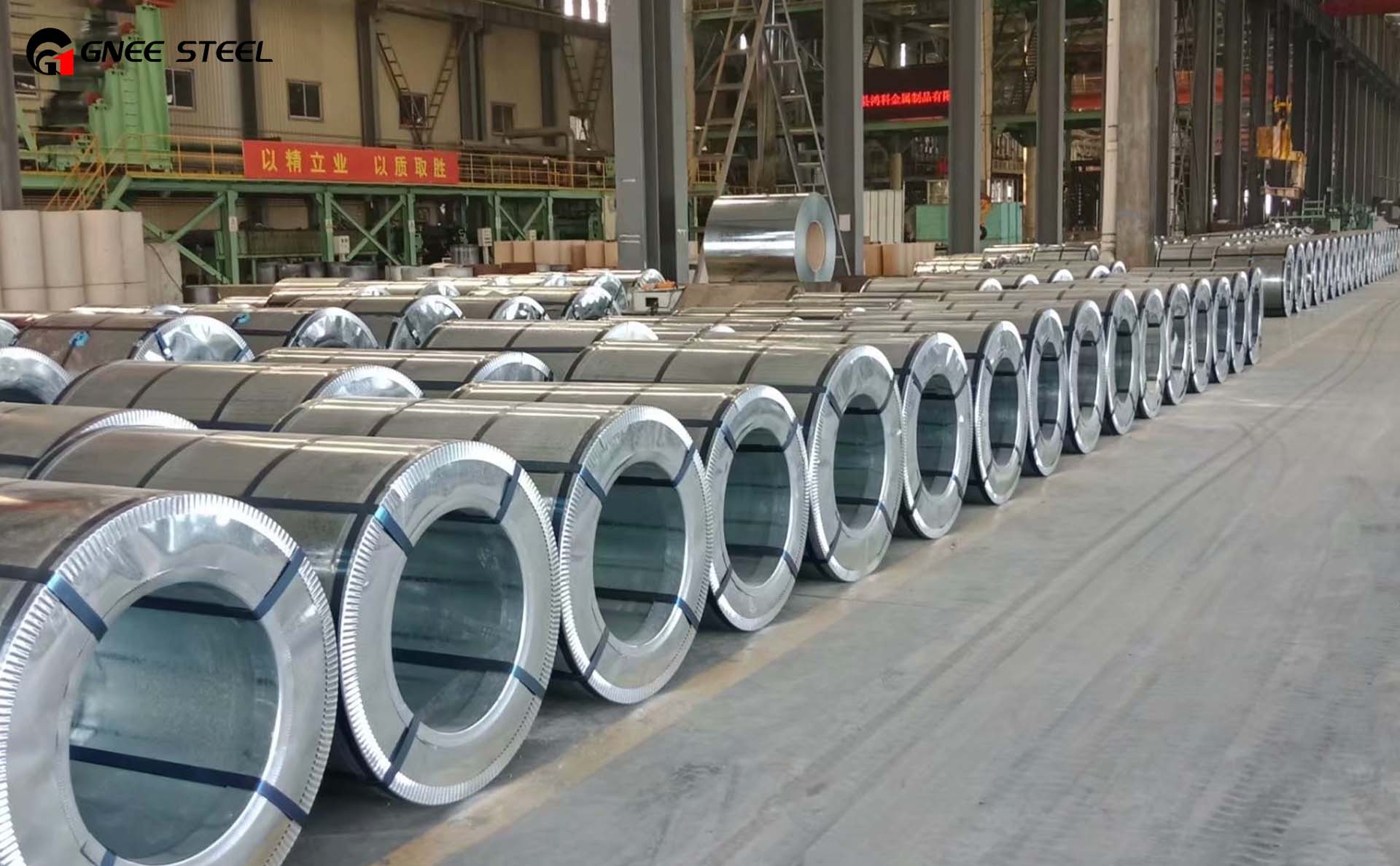

Environmentally friendly hot-dip galvanizing equipment

Intelligent hot-dip galvanizing production line is mainly composed of the following parts: raw material preparation, cleaning, hot-dip galvanizing, cooling and finished product processing. Pickling neutralizing water equipment is located in the cleaning part, which is a process in the whole production line. Its main function is to remove oxides, oil and other impurities from the metal surface to provide a clean substrate surface for subsequent hot-dip galvanizing treatment.

In an intelligent hot-dip galvanizing production line, the location of the pickling neutralizing water equipment is very important. Firstly, it is located at the beginning of the production line, which is the beginning of the whole process, so its treatment effect directly affects the quality of the subsequent processes. Secondly, pickling neutralizing water equipment plays a role in the production line, providing key surface conditions for the subsequent hot-dip galvanizing treatment. Finally, the operation of pickling neutralizing water equipment also affects the production efficiency and energy consumption, so it also plays an important role in production cost control.

The operation principle of pickling and neutralizing water equipment in intelligent hot-dip galvanizing production line is mainly to use the chemical action of acid and lye to realize the cleaning and neutralization of metal surface by controlling the parameters of acidity and alkalinity, temperature and time. Among them, the application of automatic control system and computer control system technology makes the operation of pickling neutralizing water equipment more efficient, stable and safe.

To sum up, pickling neutralization water equipment is in a very important position in the intelligent hot-dip galvanizing production line, and its running condition directly affects the quality and efficiency of the whole production line. With the continuous development of science and technology, pickling neutralization water equipment will be more intelligent, efficient and environmentally friendly, providing more powerful support for the development of intelligent hot-dip galvanizing production line.