Basic knowledge of corrugated sheets

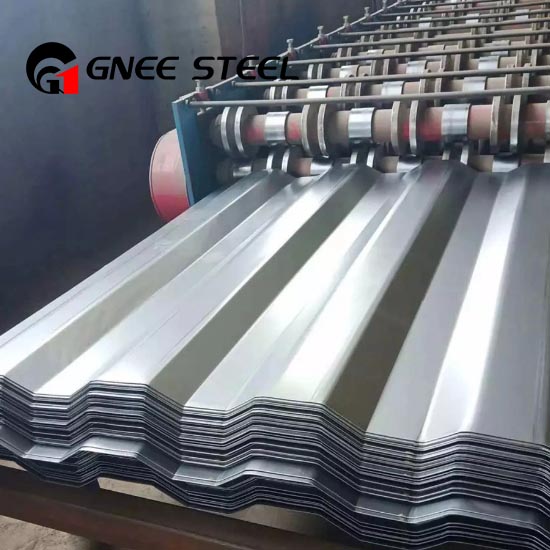

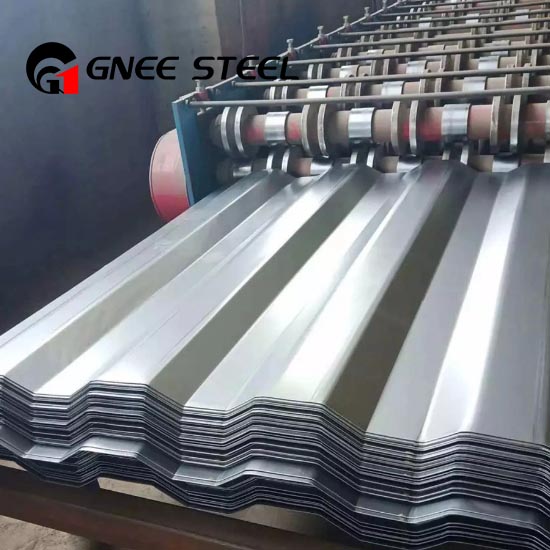

Corrugated sheets are also called profiled sheets. They are made of color-coated steel sheets,

galvanized sheets and other metal sheets that are rolled and cold-bent into various corrugated profiled sheets. It is suitable for industrial and civil buildings, warehouses, special buildings, and large-span buildings. Roofs, walls and interior and exterior wall decoration of steel structure houses. It has the characteristics of light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fireproof, rainproof, long life, maintenance-free, etc., and has been widely promoted and used.

Entering the 21st century, China's national economy has developed rapidly and steadily. Color-coated corrugated panels have also entered large-scale public buildings in various places from general industrial buildings, such as airport terminals, train stations, sports venues, concert halls, and grand theaters. In 2008 Olympic venues. The roof, floor and walls of the building adopt plate shapes with more reasonable stress and connection, and the construction method is more scientific and has stronger performance, such as galvanized plates, aluminum-magnesium-manganese alloy plates, titanium alloy plates, stainless steel, etc. The research and development has greatly improved the application technology level of sub-type metal plates.

In terms of panel structure and standards, second-generation profiled panel products such as undercut structures, snap-fit structures, and hidden fastener connections have emerged; closed profiled panel buildings have mature applications; and the coating of profiled panels has emerged. The plates (substrates) have been added to the varieties of aluminized plates and galvanized aluminum plates, and new products such as polyvinylidene fluoride (PVDF) coated plates and high weather-resistant polyester coated plates (HDP) have been added to the coated plates; related international "Continuous Hot Plating" "Zinc Steel Plate and Steel Strip", "Color Coated Steel Plate and Steel Strip", "Steel Structure Engineering Construction Quality Acceptance Code", etc. are being revised one after another.

Profiled steel plates are usually classified in a variety of ways based on application locations, plate wave heights, overlap structures, and materials. Common classification methods are as follows:

(1) Classified by application parts - divided into roof panels, wall panels, floor decking panels and ceiling panels, etc. During use, colored steel plates are also used as wall decorative panels, and the architectural decoration effect is relatively novel and unique.

(2) Classification by wave height - divided into high wave boards (wave height ≥70mm), medium wave boards and low wave boards (wave height <30mm)

(3) Classification by substrate material - divided into hot-dip galvanized substrates, hot-dip galvanized substrates, hot-dip galvanized aluminum substrates, etc.

(4) Classification according to the board seam construction method - divided into overlap, undercut and buckle structures, etc. Among them, the undercut and buckled medium and high corrugated boards should be used as roof panels with high waterproof requirements; the overlapping medium and high corrugated galvanized panels can be used as floor coverings; and the overlapping low corrugated boards should be used as wall panels.