With the continuous development of the global automobile industry and the deepening of the concept of environmental protection, lightweighting has become an important trend in the development of the automobile industry. In this context, cold-rolled automotive steel, as an important lightweight material, is gradually receiving widespread attention and application.

1. Definition and characteristics of

cold-rolled automotive steel

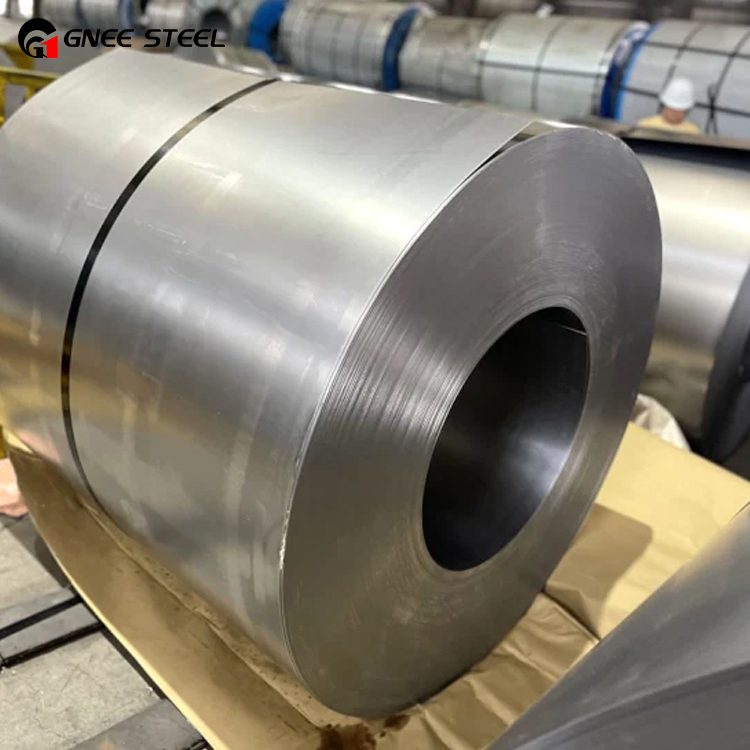

Cold-rolled automotive steel refers to steel plate materials produced through rolling processes at room temperature and used for automotive manufacturing. Compared with traditional hot-rolled steel plates, cold-rolled steel plates have higher precision, thinner thickness and better surface quality. In addition, cold-rolled automotive steel also has the characteristics of high strength, high toughness, good fatigue resistance and corrosion resistance, which provides strong support for lightweight vehicles.

2. Application of cold-rolled automotive steel in the automotive industry

Body structure: Cold-rolled automotive steel can be used to manufacture body coverings and structural parts, such as doors, hoods, roofs, etc. Its high strength and good toughness make the body structure stronger, while reducing the weight of the body and improving fuel economy.

Chassis system: Cold-rolled automotive steel can also be used to manufacture the chassis system of automobiles, such as beams, longitudinal beams, etc. Its excellent fatigue resistance and corrosion resistance ensure the reliability and durability of the chassis system.

Engine and transmission system: Cold-rolled automotive steel can also be used to manufacture key components of engines and transmission systems, such as crankcases, gears, etc. Their high strength and good wear resistance allow these components to withstand high loads and high speeds.