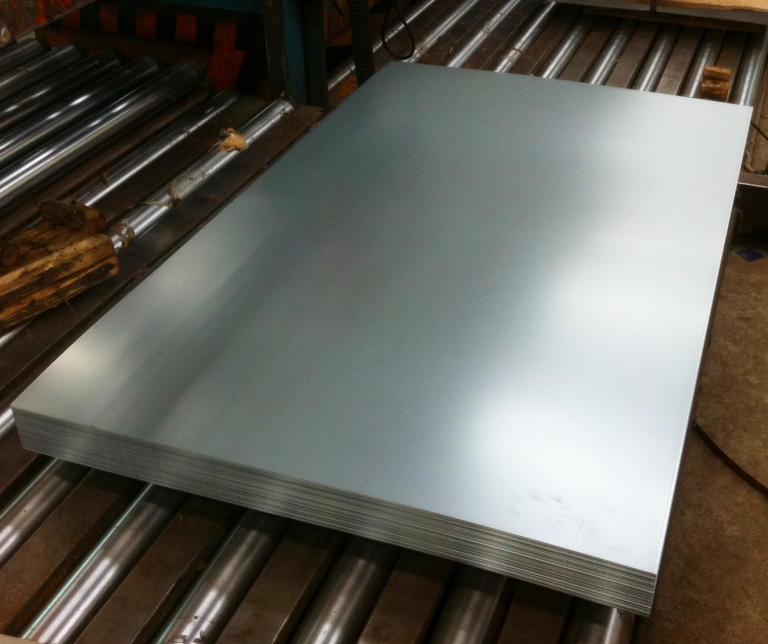

Introduction to cold rolled galvanized sheet

Cold rolling is to further thin the steel plate to a target thickness at room temperature. Compared with hot-rolled steel plates, cold-rolled steel plates have a more precise thickness,

smooth and beautiful surface, and have various superior mechanical properties, especially in terms of processing performance. Because cold-rolled raw coils are relatively brittle

and hard and not suitable for processing, cold-rolled steel plates are usually required to be annealed, pickled and surface smooth before being handed over to customers.

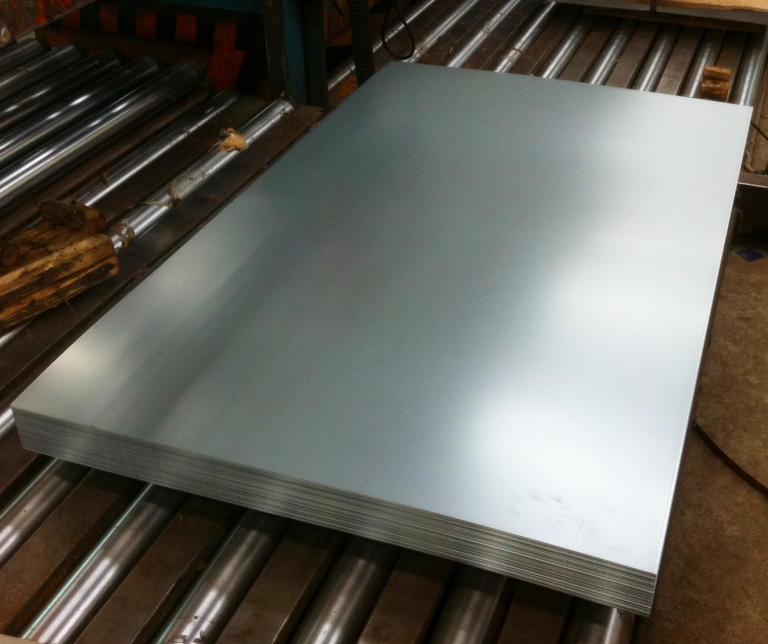

The minimum thickness of cold rolling is 0.1--8.0MM or less. The thickness of cold-rolled steel plates in most factories is less than 4.5MM. The minimum thickness and width

are determined according to the equipment capabilities and market demand of each factory.

Advantages and disadvantages of cold rolling:

Advantages: fast forming speed, high output, and does not damage the coating. It can be made into a variety of cross-sectional forms to adapt to the needs of use conditions;

cold rolling can cause large plastic deformation of steel, thereby improving the yield of the steel. point. Disadvantages: 1. Although there is no hot plastic compression during

the forming process, there are still residual stresses in the section, which will inevitably affect the overall and local buckling characteristics of the steel; 2. The cold-rolled

steel section is generally an open section, which makes the section free Torsional stiffness is low. It is prone to torsion when subjected to bending and torsional buckling

when subjected to pressure, and its torsion resistance is poor; 3. The wall thickness of cold-rolled steel is small, and there is no thickening at the corners where the plates

are connected, so it can withstand localized The ability to concentrate loads is weak.

Cold-rolled galvanized sheets are used in automobiles, refrigerators, washing machines and other home appliances, as well as industrial equipment and various building materials.