The recommended nominal Al-Zn alloy coating weight is listed in the table below. Considering the use environment of galvalume steel sheet for construction purposes, the recommended minimum nominal coating weight is 50/50 g/m².

| Coating type | Recommended coating weight |

| Al-Zn alloy | 30/30,40/40,50/50,60/60, 75/75,90/90 |

| a: Coating mass 50g/m: equals to a coating thickness of 13.3pm approximately. | |

| Item | Classification | Symbol |

| Coating type | Al-Zn alloy | AZ |

| Surface finish | Regular spangle | R |

| Minimized spangle | M | |

| Skin passed | S | |

| Surface treatment | Chromate passivated | c |

| Non-chromate passivated | C5 | |

| Chromate passivated + oiling | CO | |

| Non-chromate passivated+oiling | CO5 | |

| Anti-fingerprint | N | |

| Non-chromate anti-fingerprint | N5 | |

| Non-chromate high weather resistance anti-fingerprint | NW | |

| Oiling | 0 | |

| No treatment | U |

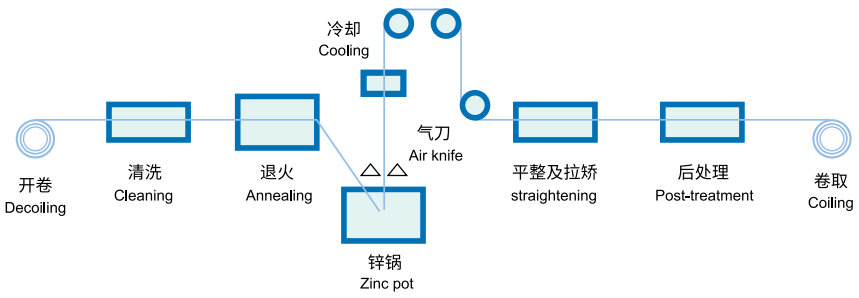

Decoiling – Cleaning – Annealing – Zinc pot – Cooling – Air knife – Straightening – Post-treatment – Coiling

Detailed Steps Of The Galvalume Steel Sheet Processing

Step 1:

Pre-treatment: After the cold-rolled coil arrives in the galvalume workshop, after passing through the uncoiler, through the degreasing section and the reduction furnace, the steel coil is cleaned and its components are reduced to the extent that it can be galvanized.

Step 2:

Central section: The most critical technology is this step. After passing through the zinc pot, a layer of zinc layer is plated on the surface of the steel plate. After coming out of the zinc pot, it is cooled and shaped by the cooling tower.

Step 3:

Post-processing: The steel plate finally comes to the post-processing stage after various processes. After finishing, straightening and passivation, and finally coiling.

Applications For Galvalume Steel Sheet

Construction: civil and industrial building roofs, facades, substrates for painted rolls, garage doors.

Industrial instruments: electric control cabinets, industrial freezers, vending machines.

Usually, building roofs are the most widely used.

FAQ

Q: Why choose us?

A: Our company have been in steel business for more than ten years, we are internationally experienced, professional, and we can provide variety of steel products with high quality to our clients

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q: Can you provide sample?

A: Yes, for regular sizes sample is free but buyer need to pay freight cost.