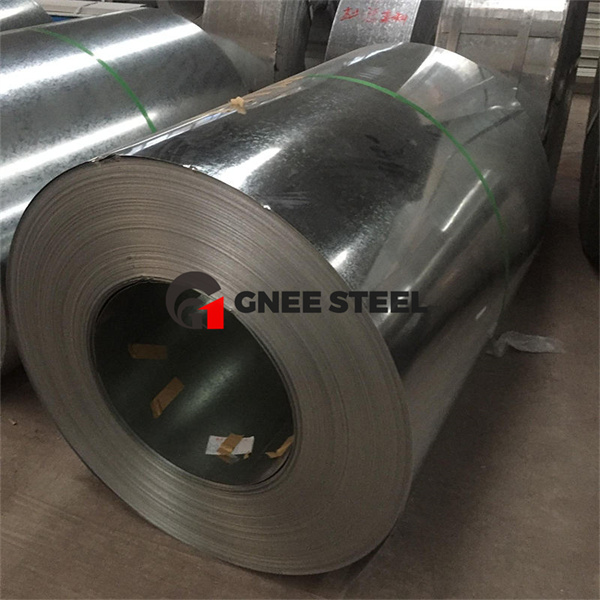

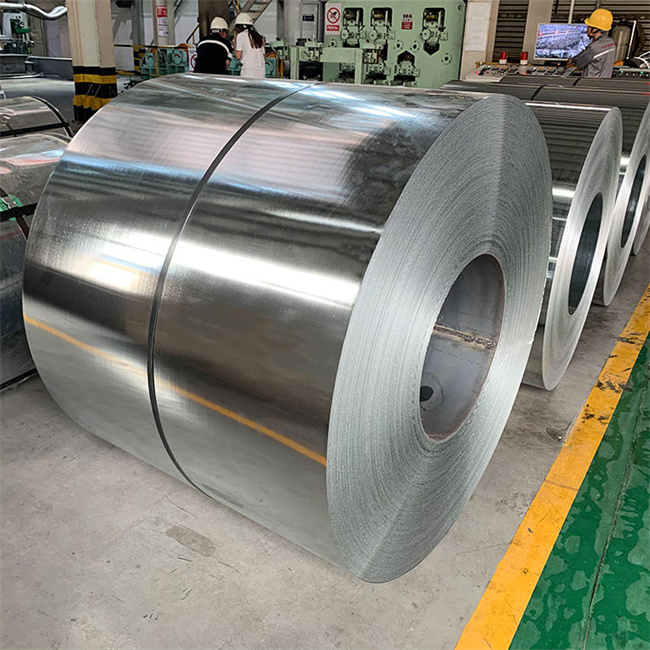

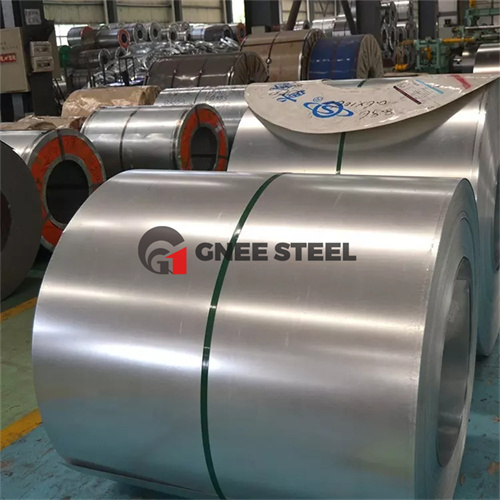

Prime hot dipped galvanized steel coil for building material

Hot dipped galvanized steel coil description:

| Standard: AISI, ASTM, BS, DIN, GB, JIS | Grade: SGCC,C2010, SGCC,C2010 |

| Thickness: 0.1-2.5MM | Width: 350—2100mm |

| Model Number: 0.23mm~1.95mm | Zinc coating: 45-130g/m2 |

| Length: as your requirement | Type: Steel Coil |

| Surface Treatment: Galvanized | Brand Name: GNEE |

| Application: Ship Plate, Ship Plate | Special Use: High-strength Steel Plate |

Prime hot dipped galvanized steel coil quick details:

The main process of hot-dip galvanized steel coil is chemically degrease and electrolytically degrease the cold-rolled coil, clean the oil on the surface of the steel strip, and then anneal in a reducing atmosphere annealing furnace, and then immersed in a molten zinc pot for hot dip galvanizing. After smoothing, tensioning, and finally passivation or oiling and other post-treatment processes. The purpose of hot-dip galvanizing is to improve corrosion resistance and extend the service life of the material, while having an aesthetic surface and increasing the artistic effect.

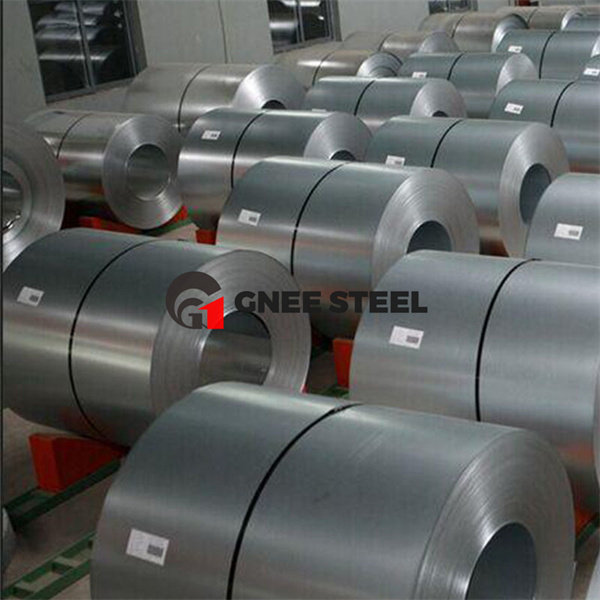

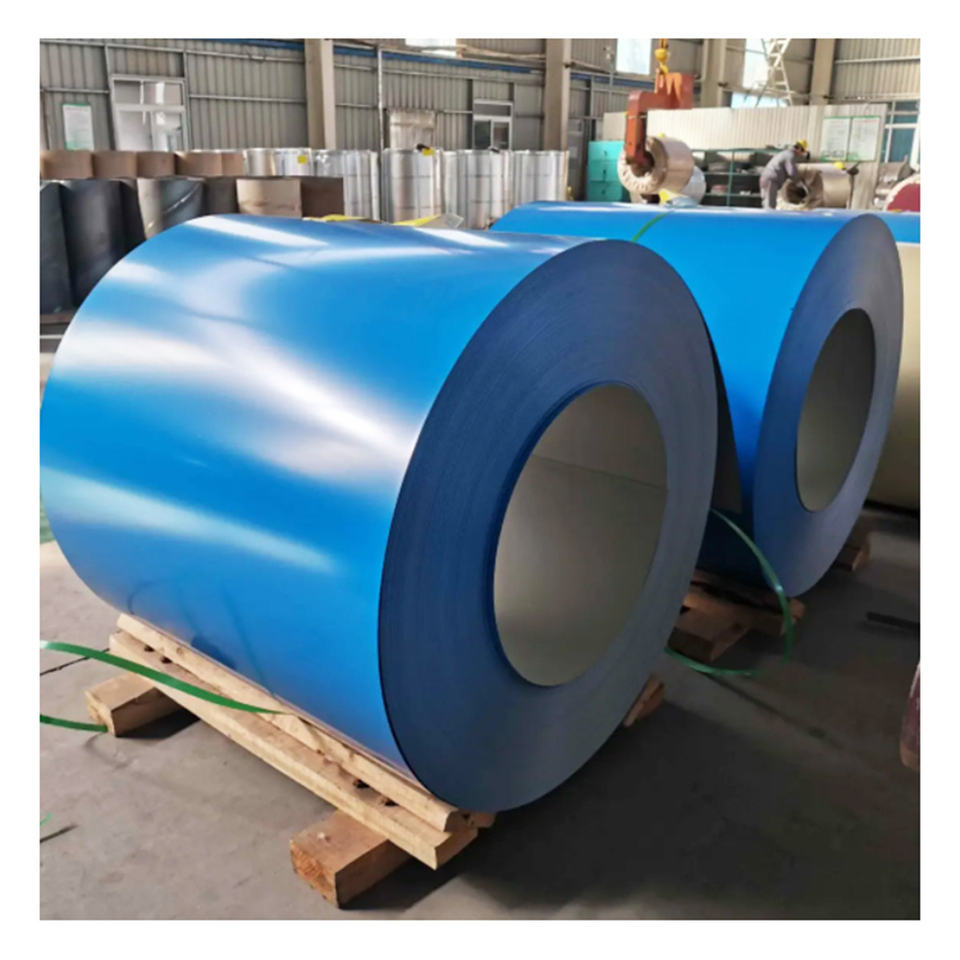

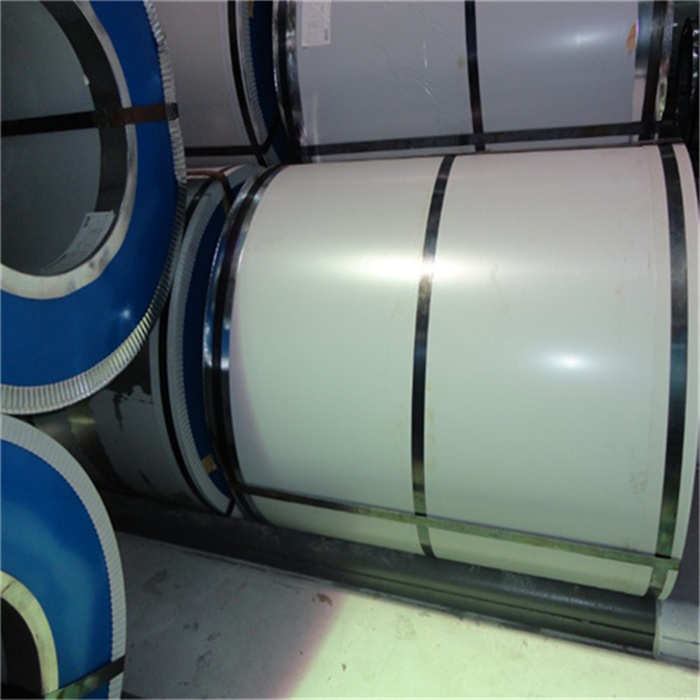

Hot-dip galvanized steel sheets are widely used in the light industry, home appliances, automotive and construction industries. In the construction industry, light steel keels, air conditioning ventilation systems, building slabs, corrugated panels, rolling shutters, etc. for various industrial and civil buildings. At the same time, hot-dip galvanized steel is also the main raw material for the production of color-coated steel sheets.

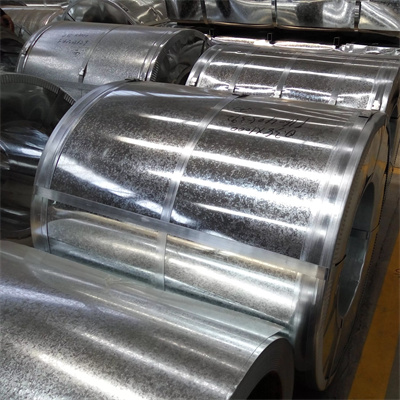

Prime hot dipped galvanized steel coil for building material Advantages:

1、We have our own factory to produce our hot dipped galvanized steel coil products.

2、Low processing costs: hot galvanizing rust is cheaper other paint coatings.

3、Comprehensive protection: every part of the plated parts can be coated with zinc, which is fully protected even in recesses, sharp corners and hidden places.

Our Email: info@gescosteel.com.