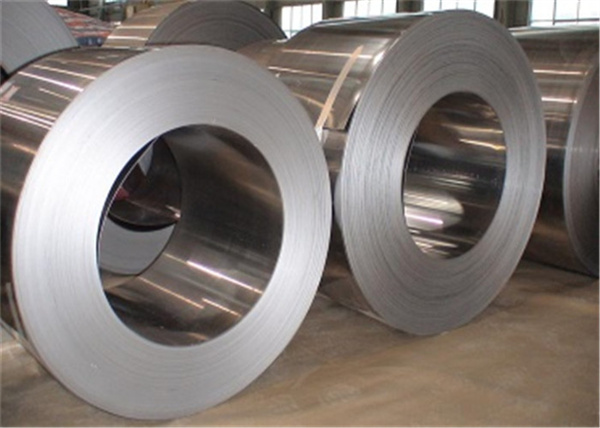

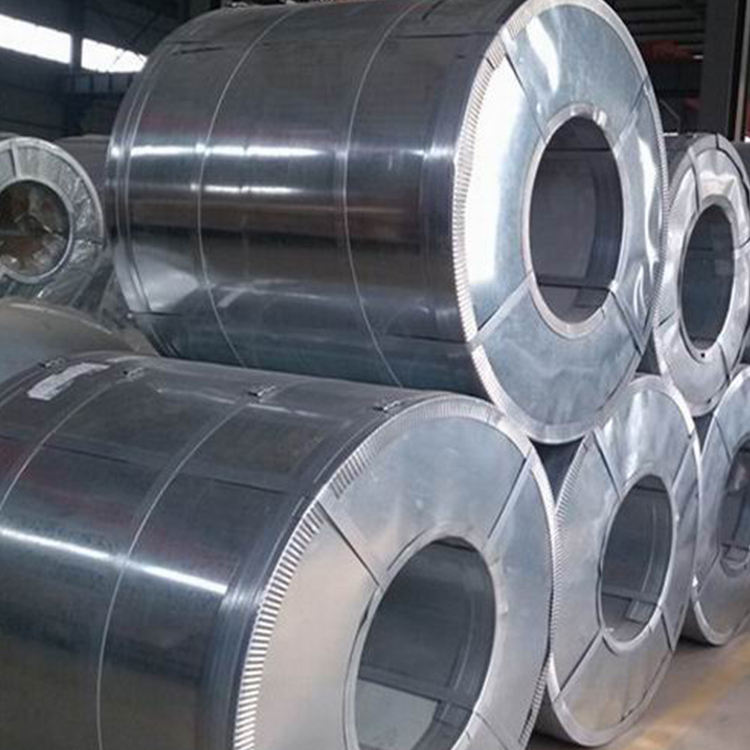

Pre-painted cold rolled galvanised steel strip/coil

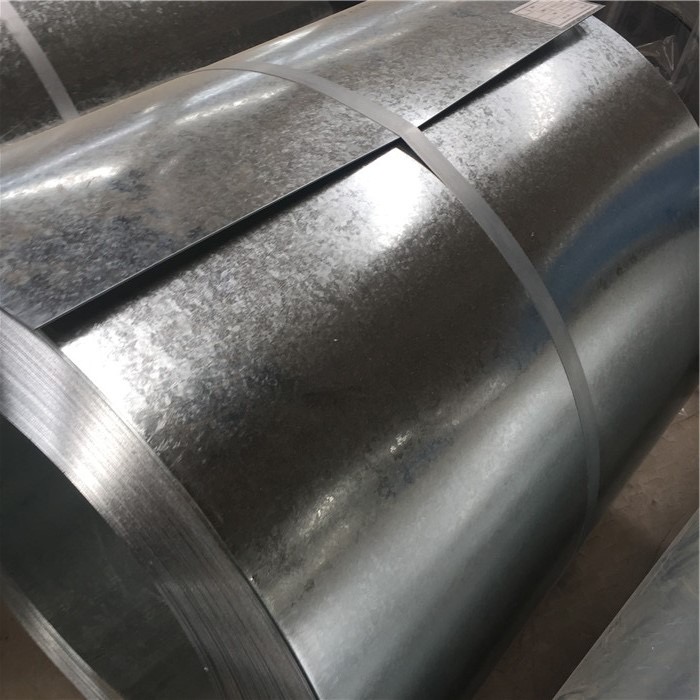

The galvanization process involves coating the steel strip with a layer of zinc, which helps protect it against corrosion and rusting. The pre-painted process involves applying a layer of paint to the surface of the galvanized steel, which provides an additional layer of protection against corrosion and rusting, as well as improving its aesthetic appeal.

Pre-painted cold rolled galvanized steel strip/coil is commonly used in a variety of applications, including roofing, siding, gutters, and downspouts in construction, as well as in appliances, automotive components, and other industrial products.

The advantages of using pre-painted cold rolled galvanized steel strip/coil include its durability, corrosion resistance, and low maintenance requirements. It also has good formability, meaning it can be easily shaped and bent into various shapes and sizes. Additionally, the pre-painted surface provides an attractive finish that can be customized to suit a wide range of aesthetic requirements.

|

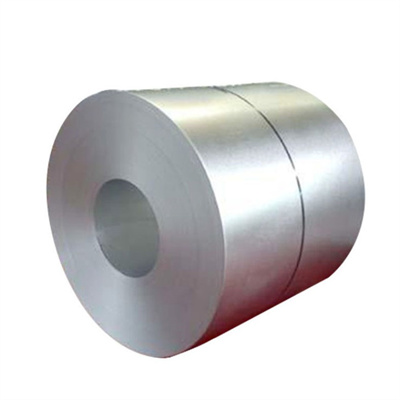

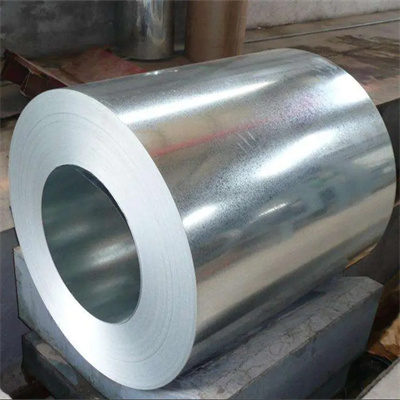

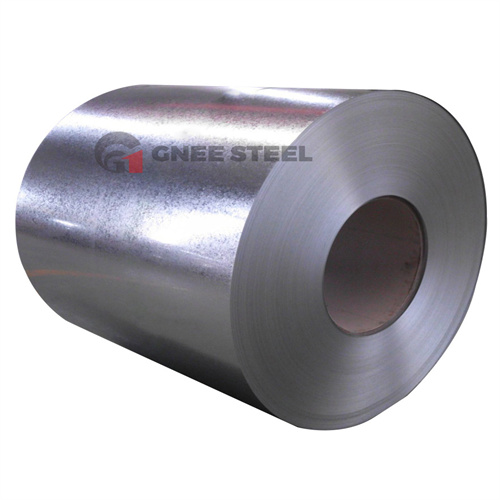

Name

|

Galvanized steel coil / sheet

|

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

|

Grade

|

Q235 Q195 SGCC,SGCH,DX51D,DX52D,DX53D DC01 DC02

|

|

Width

|

700-1830mm

|

|

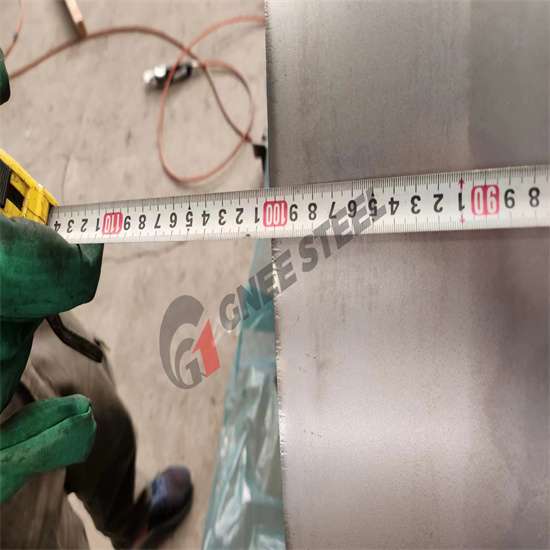

Thickness

|

0.3-3.5mm

|

|

Technique

|

Hot rolled, Cold Rolled

|

|

Suface Treatment

|

Hot dipped galvanized, Electronic galvanized

|

|

Usage

|

Costruction industry / fabrication industry / home decoration / medical devices / building materials / chemistry / food industry / agriculture

|

|

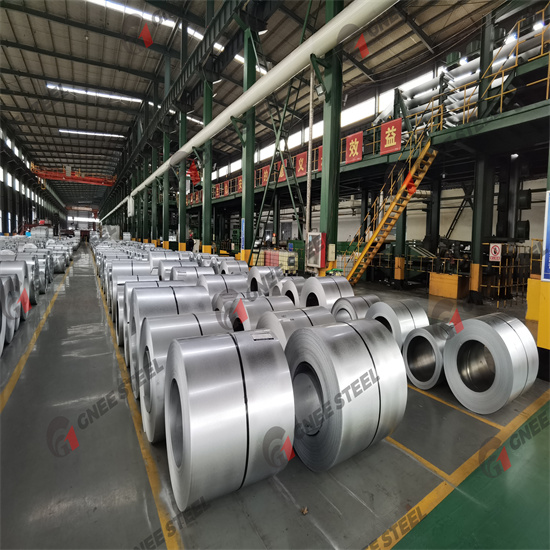

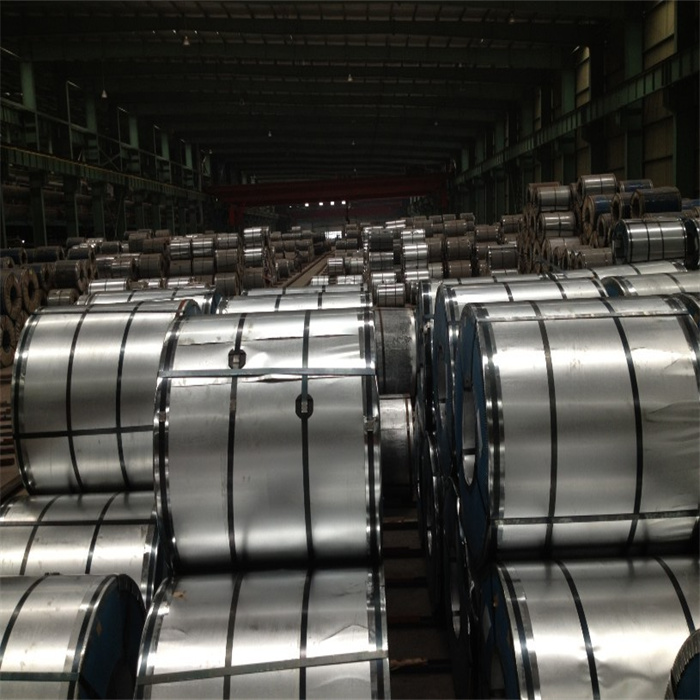

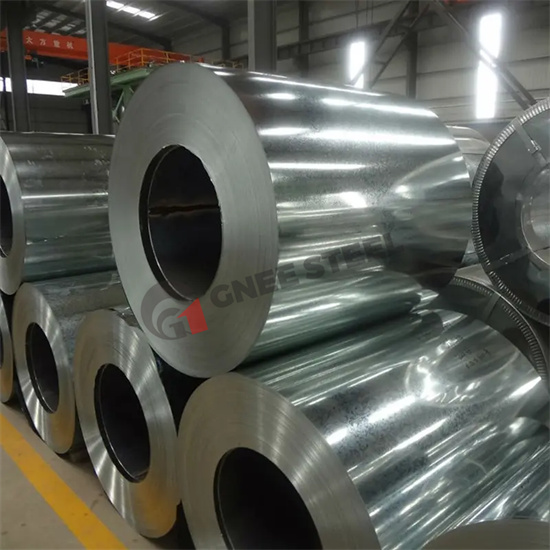

Supply Ability

|

5000 tons / month

|

|

Payment Terms

|

T/T , L/C

|

FAQ

- What about the delivery time?Normal mold time: 10-12 days Machined parts: 3-5 days Batch: 10-15 days depends on quantity.

- What is the QC system?We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot. According to the standard we will inspect every producing step.

- How many tons one 20 GP or 40 GP could load?One 20 GP could load about 20 tons. And 40 GP load about 24 tons. It depends on the different specification.

- What’s your payment term? Usually we do TT and LC or combined.

- What’s your trade term?Usually we do CIF,FOB,EXW,CNF.

- How about your after-service?Quality issue,If it is our fault,100% remake or as customer’s requirement,if not our fault,try our best to give some discount to remake.