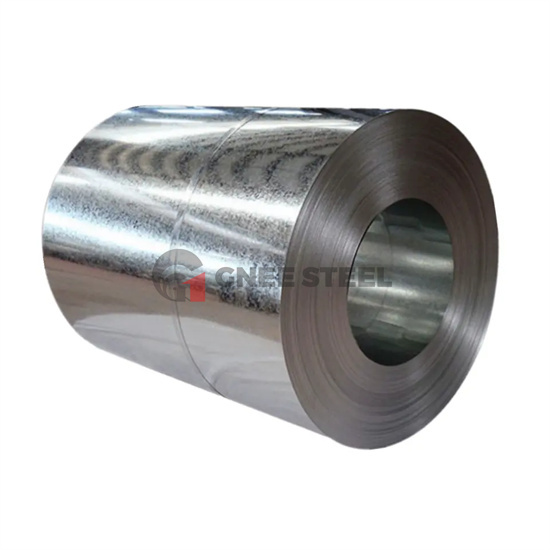

Innovations in Galvanized Steel Coil Technology

In recent years, there have been significant technological innovations in the production of galvanized steel coils, resulting in improved performance and a range of new applications. These innovations include advanced coating technologies, new steel alloys, and precision manufacturing processes, which have led to stronger, lighter, and more efficient products.

| Product Name | Specifications |

|---|---|

| Galvanized Steel Sheets | Thickness: 0.12-4.0 mm; Width: 600-1500 mm; Zinc Coating: 60-275 g/m2 |

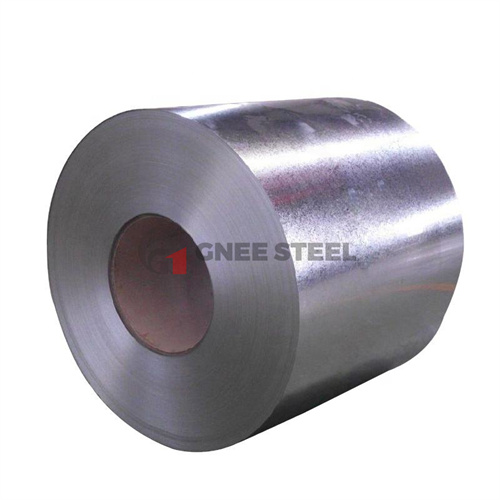

| Galvanized Steel Coils | Thickness: 0.12-4.0 mm; Width: 600-1500 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Strips | Thickness: 0.12-4.0 mm; Width: 30-600 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Tubes | Outer Diameter: 15-165 mm; Wall Thickness: 0.6-2.5 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Wire | Diameter: 0.8-6.0 mm; Zinc Coating: 60-275 g/m2 |

General Information:

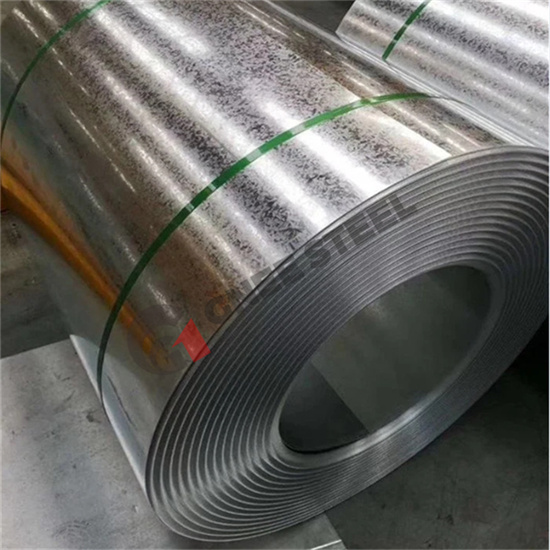

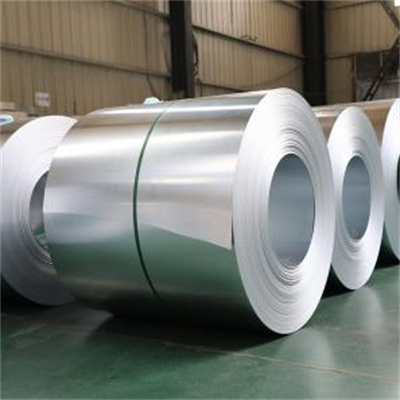

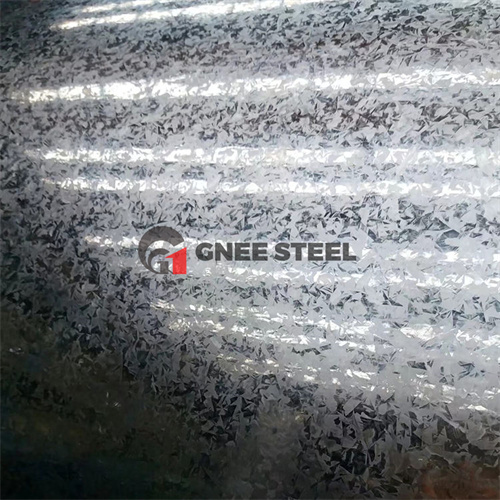

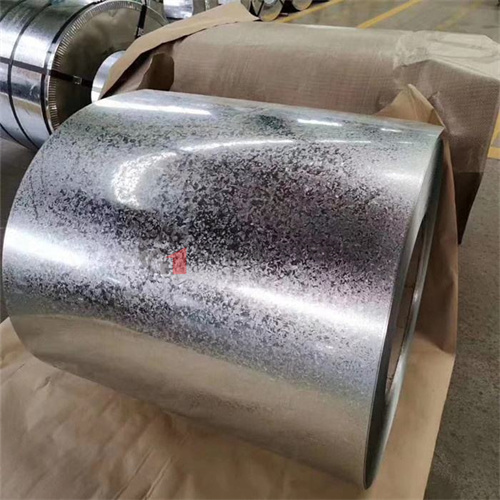

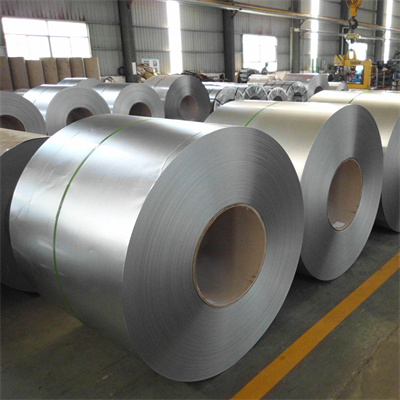

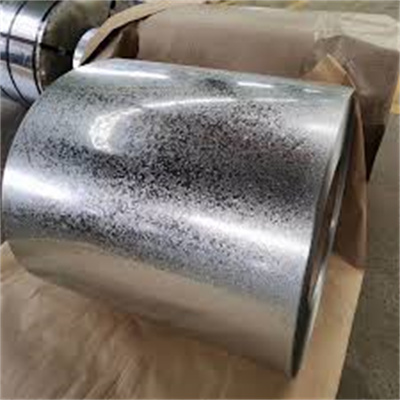

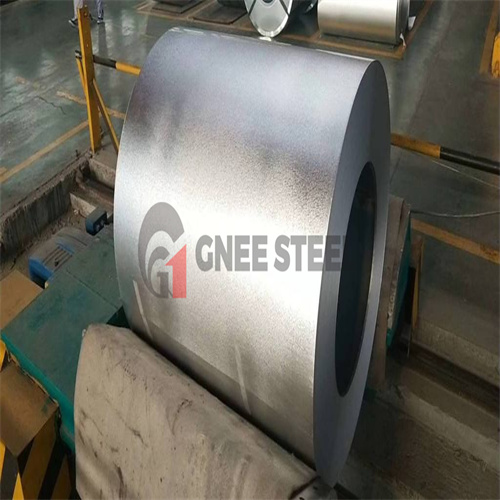

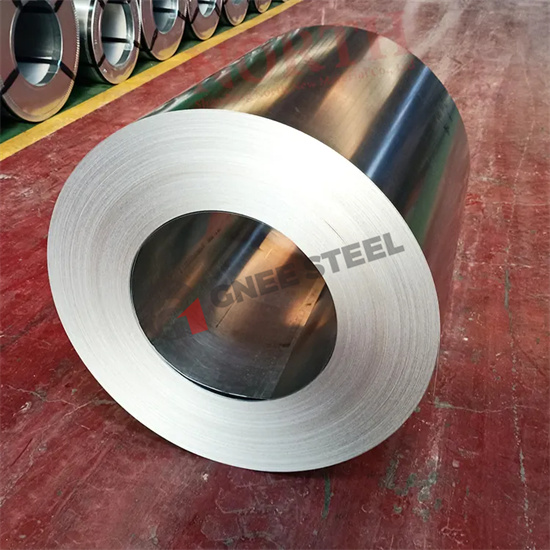

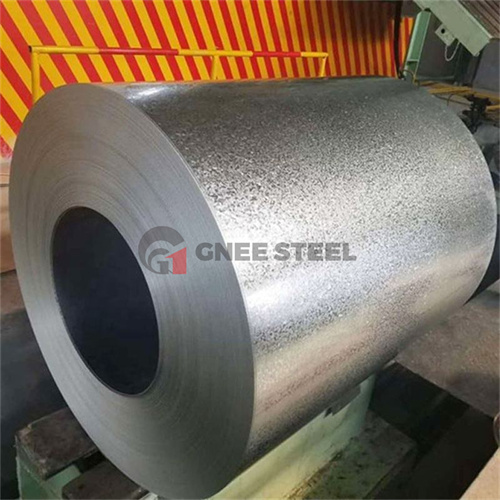

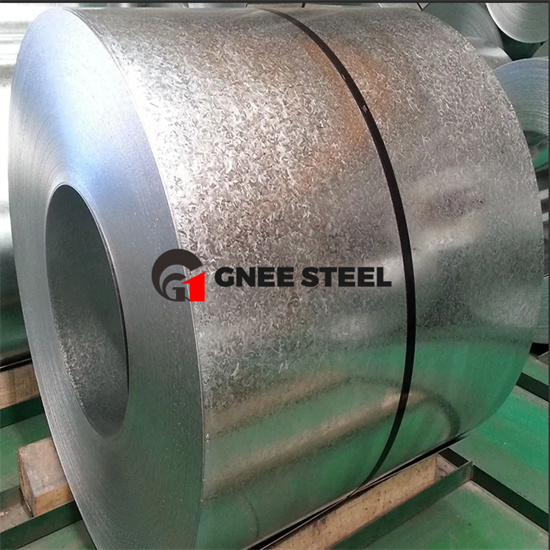

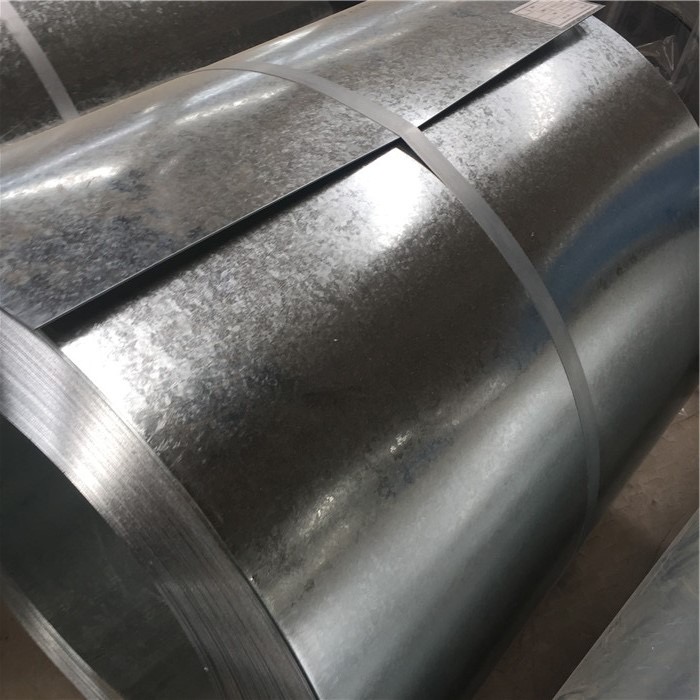

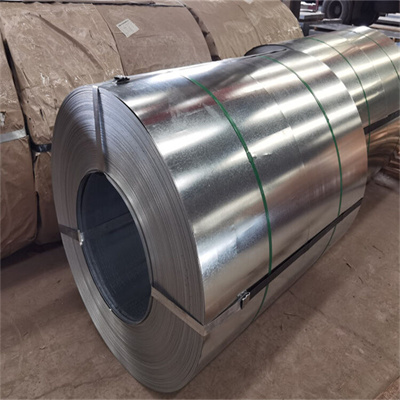

Galvanized steel coils are made from hot-dip galvanized steel, which is coated with a layer of zinc to protect the steel from corrosion. The process involves immersing the steel in a bath of molten zinc, which creates a metallurgical bond between the zinc and steel. Galvanized steel coils are widely used in construction, automotive, and other industries due to their strength, durability, and resistance to corrosion.

Company Advantages:

Our company is committed to providing customers with the latest technological innovations in the production of galvanized steel coils. We invest in research and development to continuously improve our products, and we use state-of-the-art equipment and precision manufacturing processes to ensure consistent quality and performance. Our galvanized steel coils are known for their excellent corrosion resistance, durability, and strength, and are used in a wide range of applications. We pride ourselves on providing exceptional customer service and support, and we work closely with our customers to ensure their satisfaction with our products.