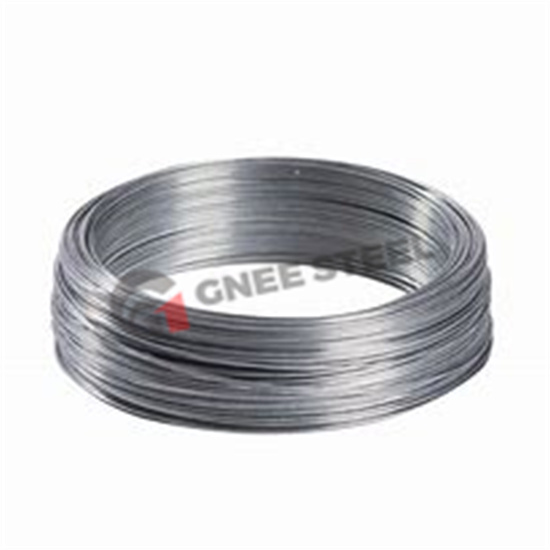

Hot dipped galvanized wire

The hot-dip galvanizing process involves cleaning the wire surface to remove any impurities, then immersing the wire in a bath of molten zinc. The zinc bonds with the wire to form a protective laye...

Contact US

Get Price

Share:

Previous:

GSB – Galvanized Steel Strip

Next:

Cold galvanized wire

Content

The hot-dip galvanizing process involves cleaning the wire surface to remove any impurities, then immersing the wire in a bath of molten zinc. The zinc bonds with the wire to form a protective layer that prevents rust and corrosion. The thickness of the coating can be controlled by adjusting the immersion time and the temperature of the zinc bath.

Hot dipped galvanized wire is commonly used in a wide range of applications, including fencing, mesh, construction, and agriculture. It is also used for making wire rope, stranded cable, and other types of wire products that require high strength and resistance to corrosion.

| Diameter (mm) | Tensile Strength (Mpa) | Zinc Coating (g/m2) |

|---|---|---|

| 0.5 | 350-550 | 15-30 |

| 0.6 | 350-550 | 15-30 |

| 0.7 | 350-550 | 15-30 |

| 0.8 | 350-550 | 15-30 |

| 0.9 | 350-550 | 15-30 |

| 1.0 | 350-550 | 15-30 |

| 1.2 | 350-550 | 15-30 |

| 1.5 | 350-550 | 15-30 |

| 1.8 | 350-550 | 15-30 |

| 2.0 | 350-550 | 15-30 |

The main advantages of GNEE Company are:

- Professional steel suppliers: GNEE has professional steel suppliers who can provide high-quality steel products;

- Global sales network: GNEE Company has a perfect sales network in the world, which can meet the needs of customers;

- Professional technical support: GNEE company has a professional technical support team, can provide professional technical support for customers;

- Excellent service: GNEE Company has excellent service team, can provide customers with excellent service.

Inquiry

More Galvanized wire