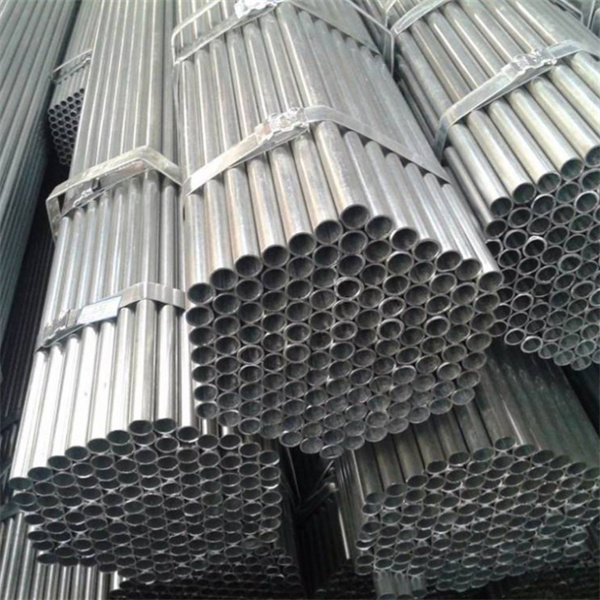

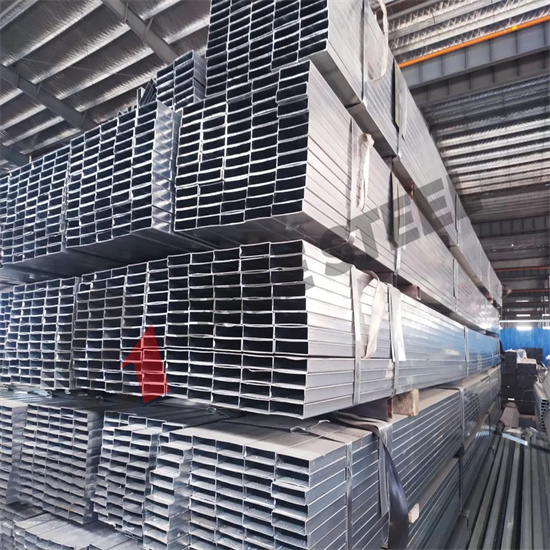

Hot dipped galvanized steel tube Hollow

Hot dipped galvanized steel tube hollow refers to a type of steel tube that has been treated with a process known as hot-dip galvanization. In this process, the steel tube is dipped into a bath of molten zinc, which coats the surface of the steel and provides protection against corrosion.

The term “hollow” typically refers to the fact that the steel tube has a hollow interior, meaning that it is not a solid piece of metal. Instead, it is often used in applications where strength and durability are important, but weight is also a consideration.

Hot dipped galvanized steel tube hollow is commonly used in a variety of industries, including construction, automotive, and manufacturing. It is often used for applications such as fencing, scaffolding, and structural support.

|

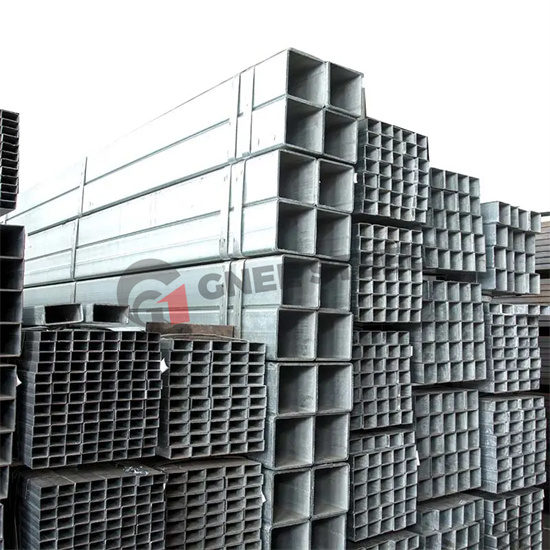

Material type

|

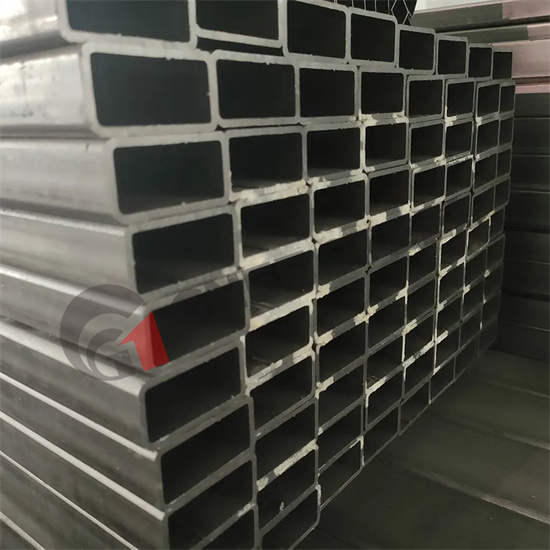

hot rolled weld square round rectangle steel pipe

|

|

Out diameter

|

10-600mm

|

|

Thickness

|

0.5-30.0mm

|

|

Length

|

3-12m or as per customers’ requirements

|

|

Material

|

Q195—Grade B, SS330, SPC, S185

Q215—Grade C,CS Type B, SS330, SPHC Q235—Grade D, SS400, S235JR, S235JO, S235J2 Q345—SS500, ST52 |

|

Standard

|

GB/T13793-1992,GB/T14291-2006, GB/T3091-1993,GB/T3092-1993,GB3640-88

BS1387/1985,ASTM A53/A36,EN39/EN10219,API 5L,GB/T9711.1-99 etc |

|

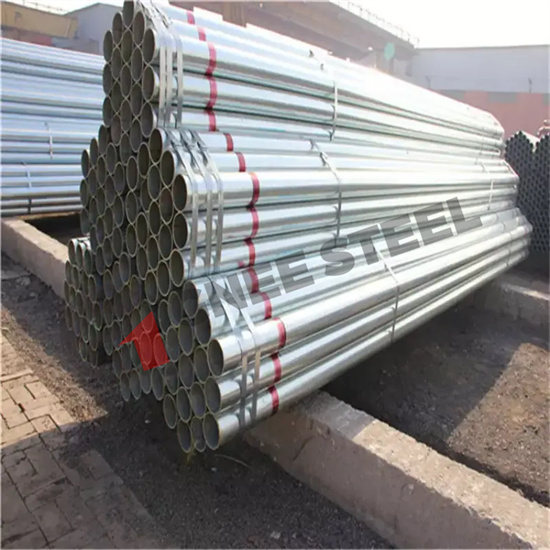

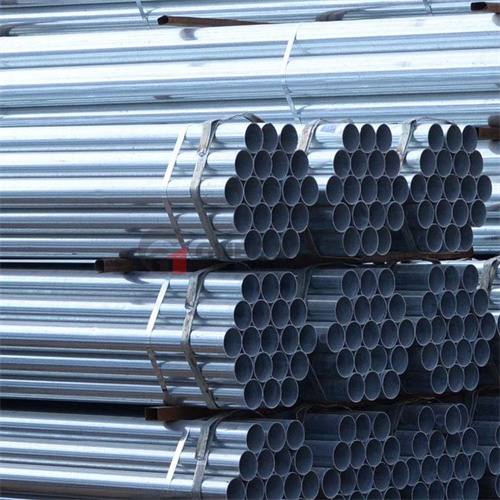

Surface treatment

|

Galvanized,or black

|

|

Zinc coating

|

pre galvanized steel pipe: 60-150g/m2

hot dipped galvanized steel pipe:200-400g/m2 |

|

Application

|

Widely used in Structure, Accessorize,Construction,

Fluid transportation,machinery parts,the stress parts of the automobile tractor parts and so on |

|

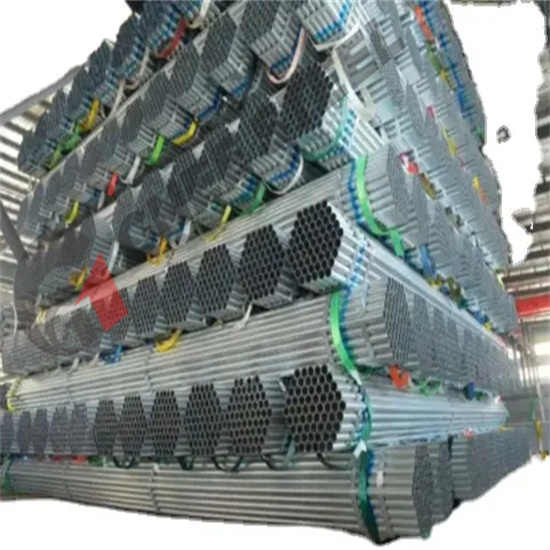

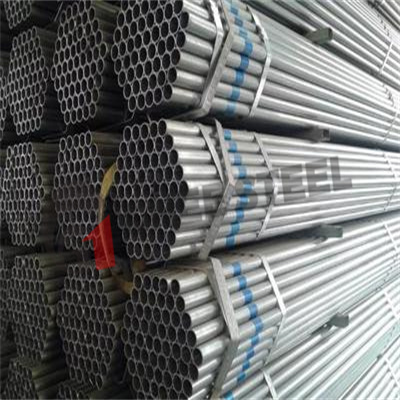

Package

|

1) Big OD: in bulk

2) Small OD: packed by steel strips 3) Plastic bags 4) According to customer’s requirement 5) 25 tons/container and 5 tons/size for a trial order;

6) For 20″ container the max length is 5.8m; 7) For 40″ container the max length is 11.8m. |

|

MOQ

|

2MT as trial order

|

|

Delivery time

|

Within 7-15 days after receiving the 30% TT deposit

|

|

Payment

|

30%TT in advance and the balance against the copy of B/L or irrevocable L/C at sight

|

GNEE has modern equipment, advanced process, unique heat treatment technology, online quenching, stabilizing product performance, ensuring higher product yield and strictly controlling product quality.