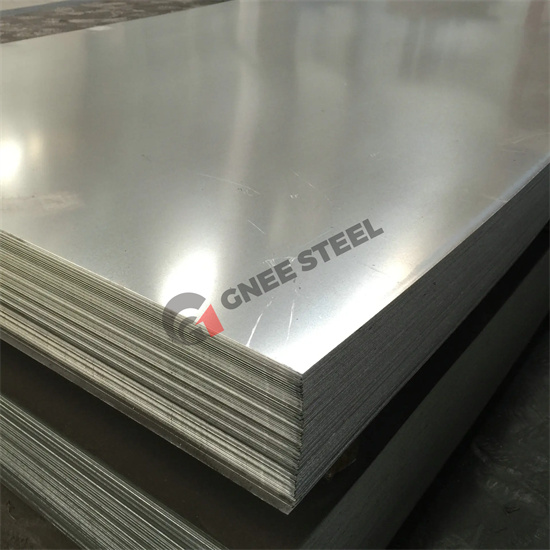

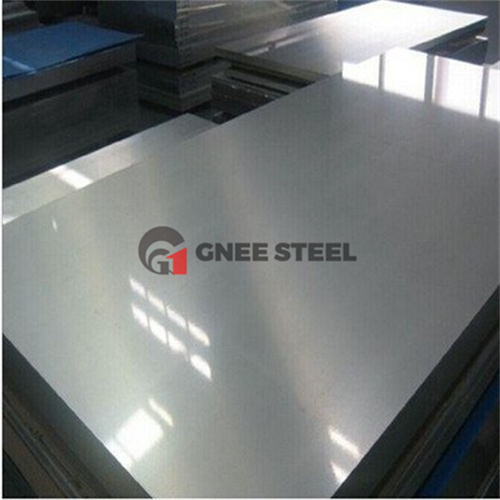

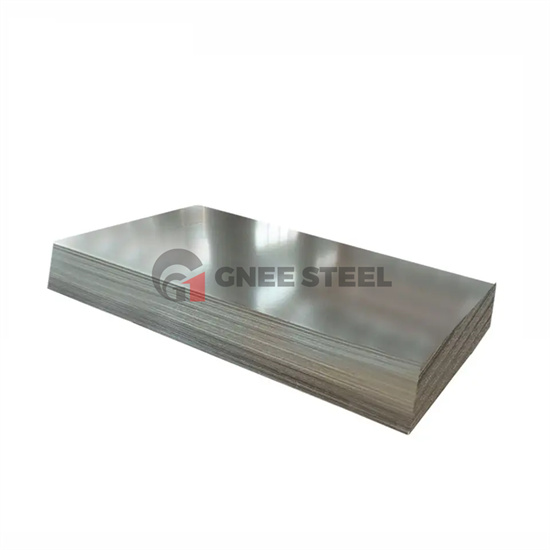

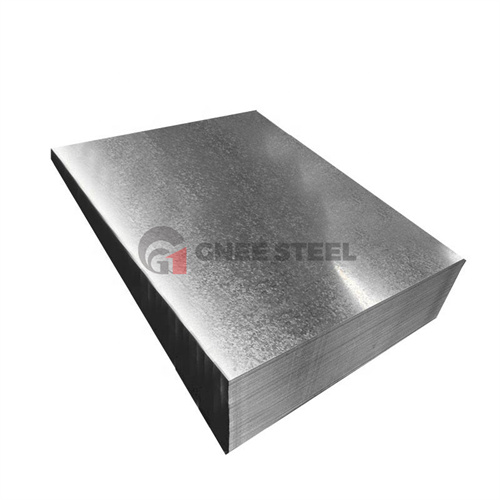

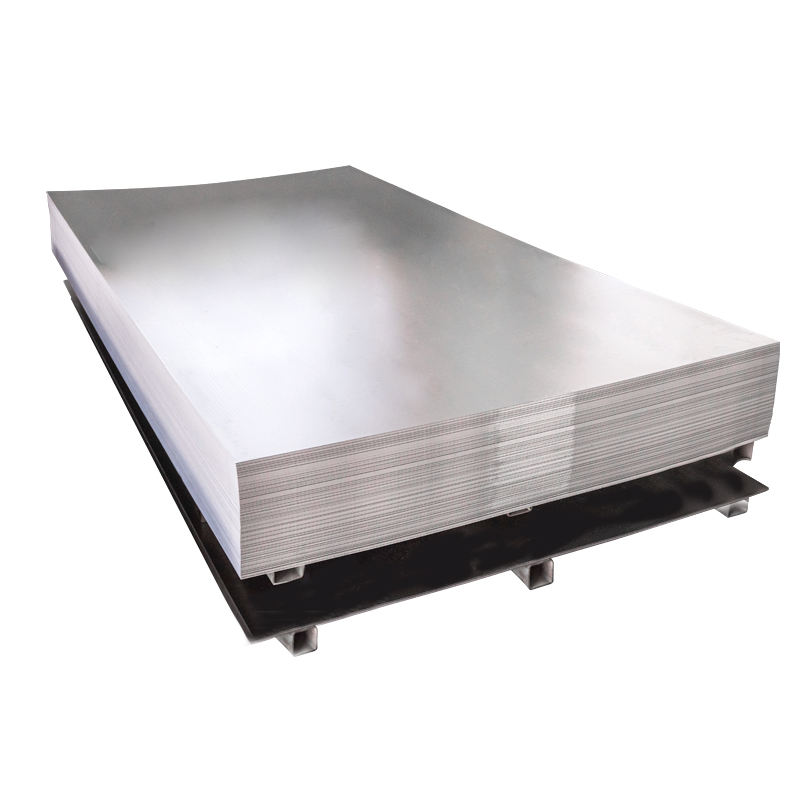

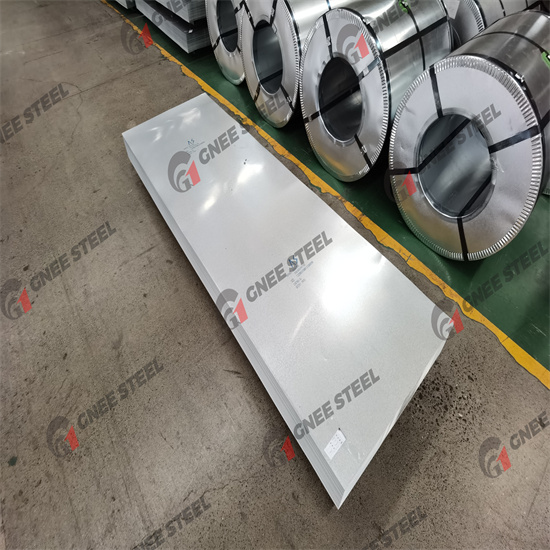

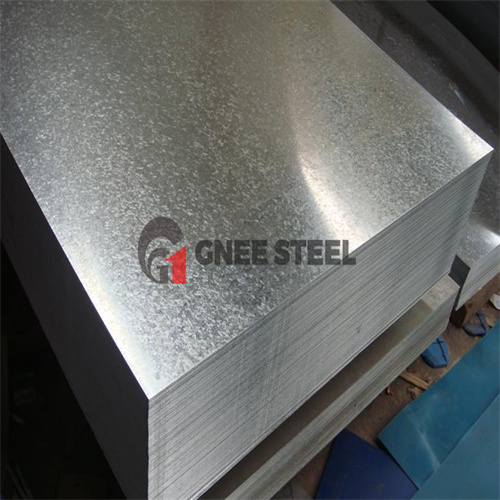

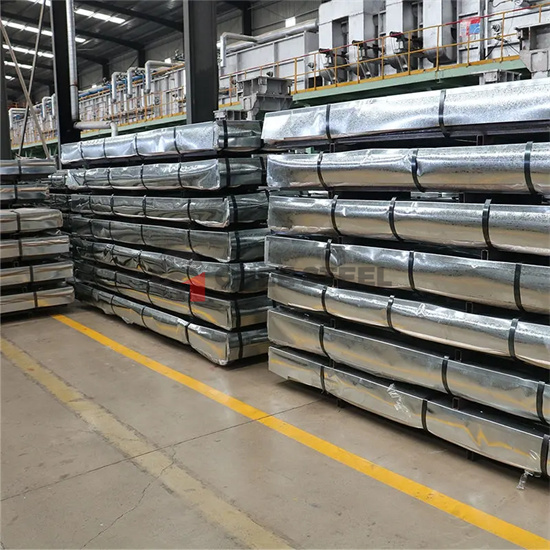

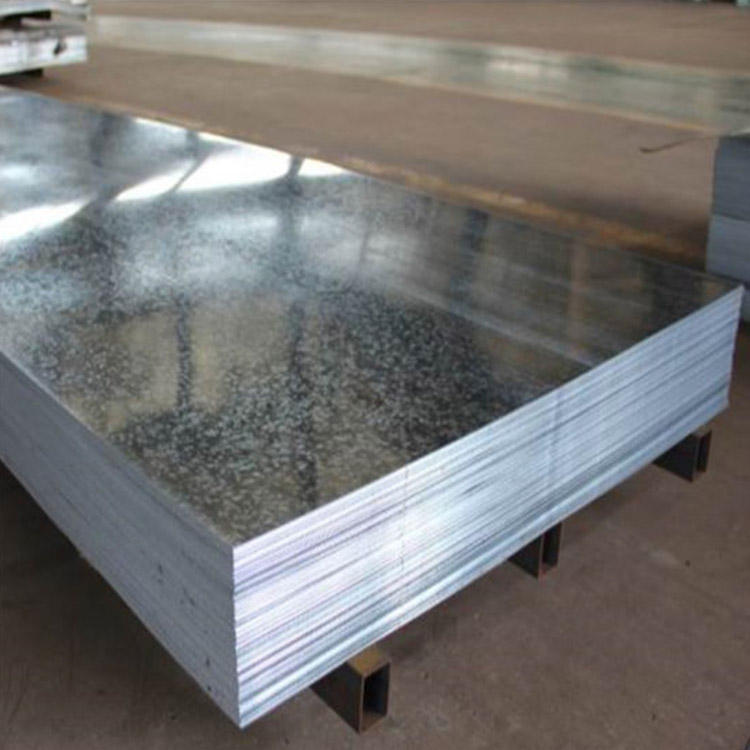

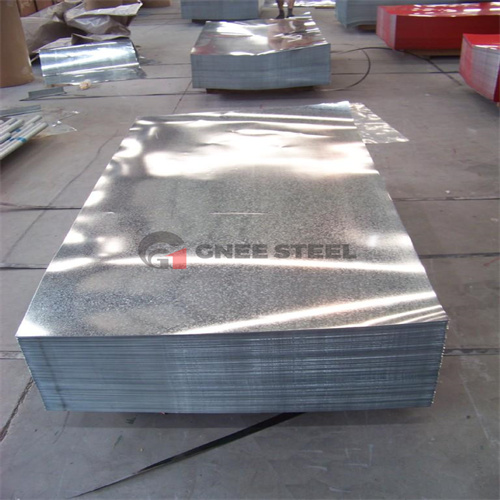

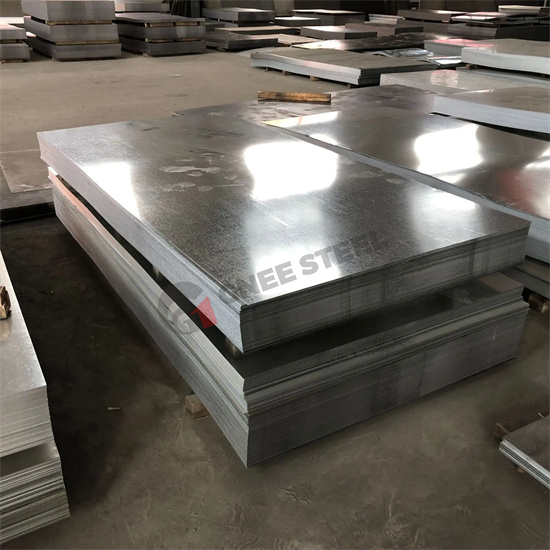

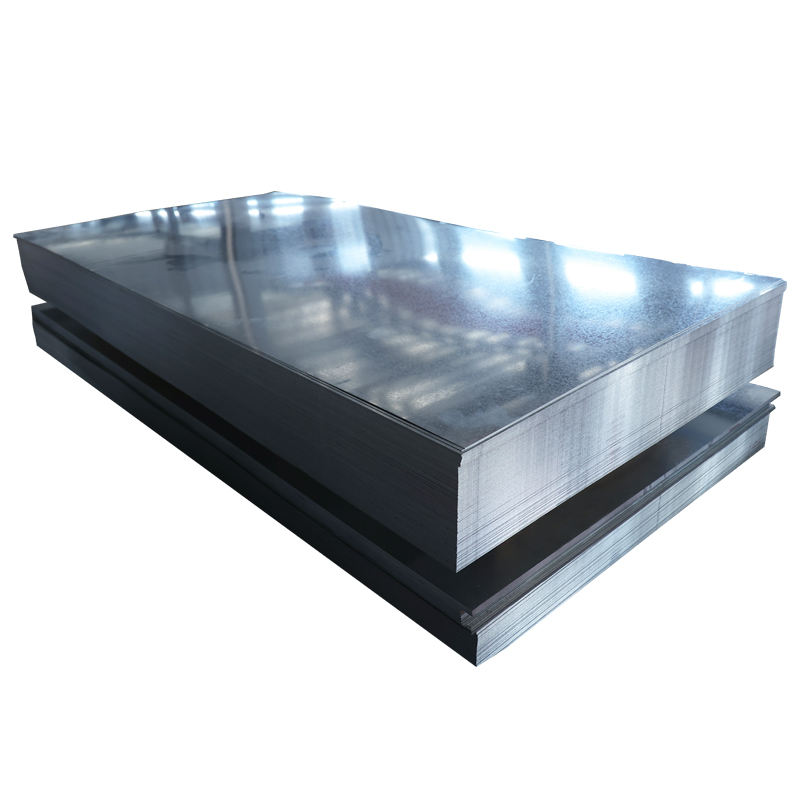

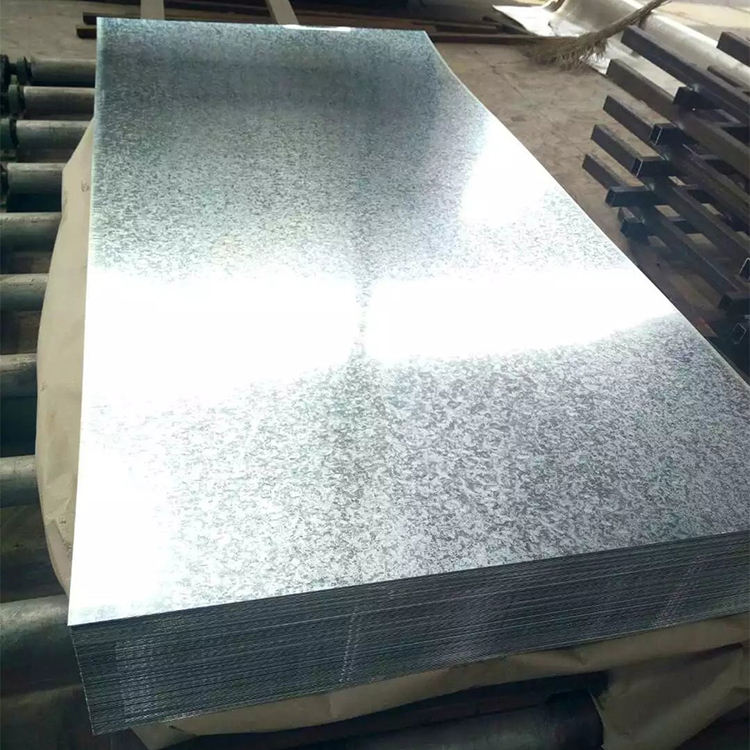

Hot-dipped galvanized steel sheets

Hot-dipped galvanized steel sheets

There are thousands of galvanizing methods,Only hot-dip galvanizing is the most powerful!

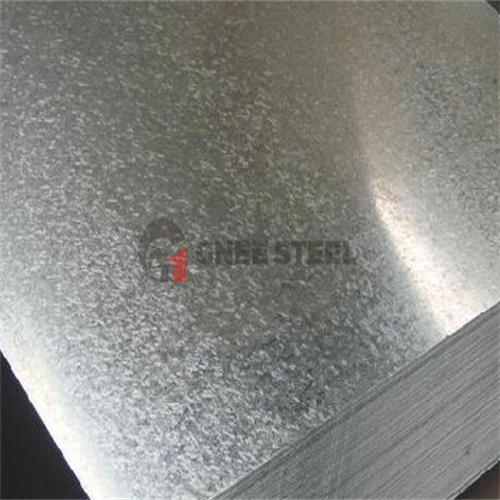

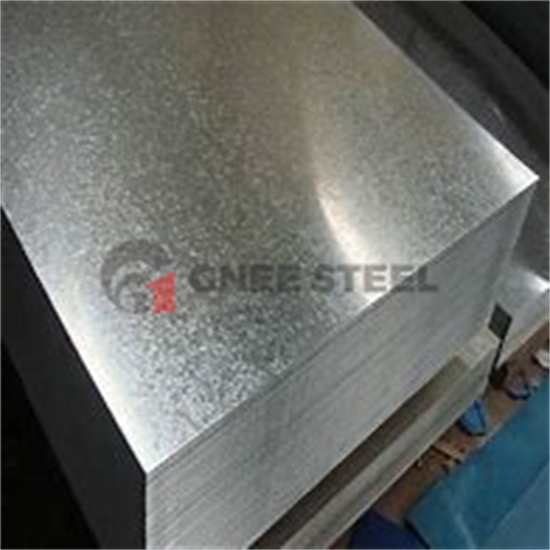

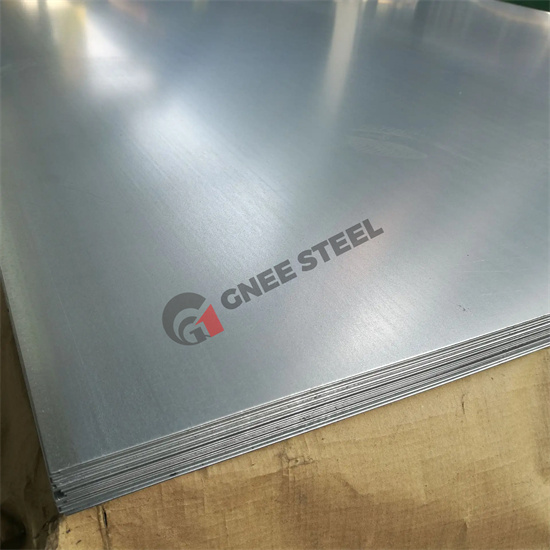

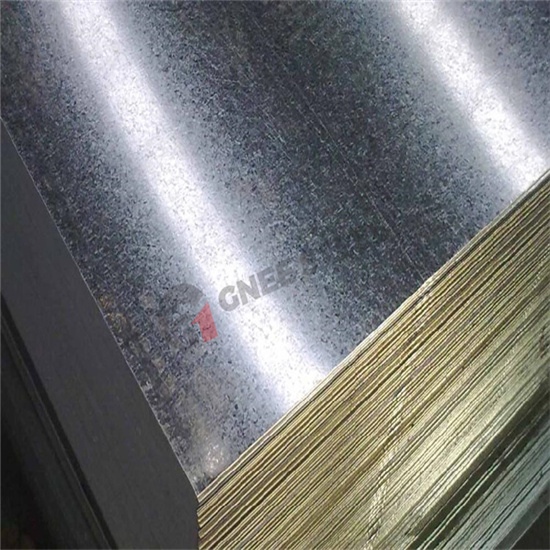

Hot-dip galvanizing: Hot-dip galvanizing is a process in which molten metal reacts with an iron substrate to produce a zinc-iron alloy layer, thereby combining both the substrate and the coating. Hot-dip galvanizing is a process in which the steel parts are first pickled, in order to remove iron oxide from the surface of the steel parts. After pickling, they are cleaned by passing through a bath of ammonium chloride or zinc chloride in aqueous solution or a mixture of ammonium chloride and zinc chloride in aqueous solution, and then sent to a hot dip plating bath.

Hot-dipped galvanized steel sheets Advantages: uniform plating, strong adhesion, long service life.

| Standard | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518,

European Standard, ASTM A792, JIS G3321, JIS G3317 |

| Base Plate | Cold rolled steel sheet, hot dipped zinc coated steel sheet, hot dipped A-Z coated

steel sheet |

| Equipment | Double coating double baking; three coating three painting |

| Capacity | 500,000Mt/year |

| Zinc Coating | 30g-270g |

| Coil Weight | 2.5Mt-8Mt |

| Coil ID | φ508mm-φ610mm |

| Base Sheet | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle),

hot dipped A-Z coated steel sheet |

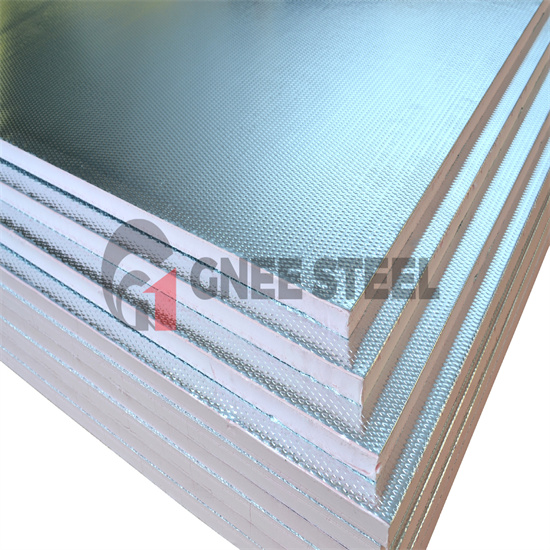

| Surface Paint | EP, PE, HDP, SMP, PVDF |

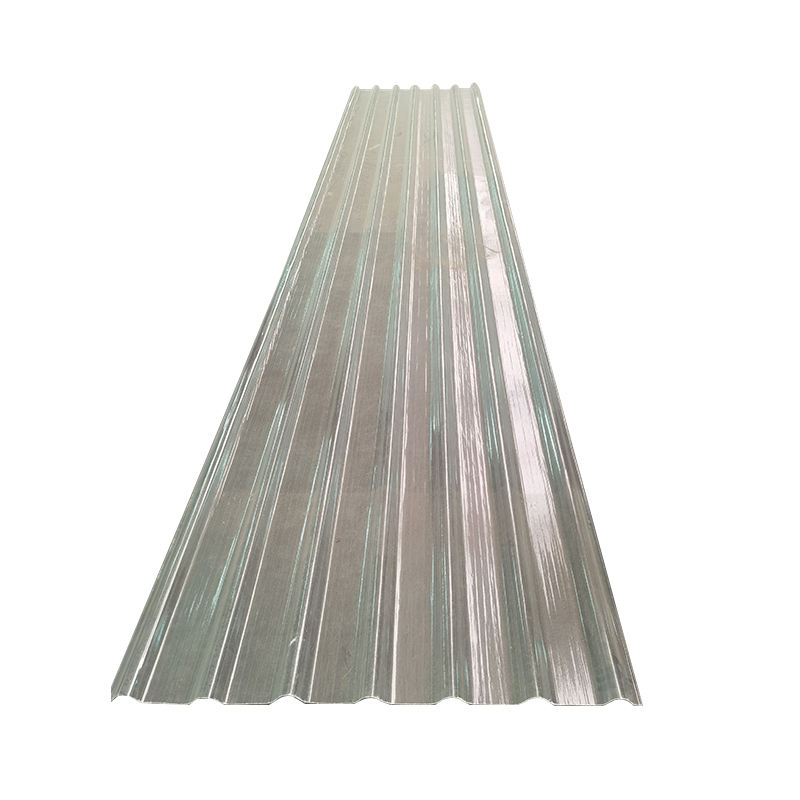

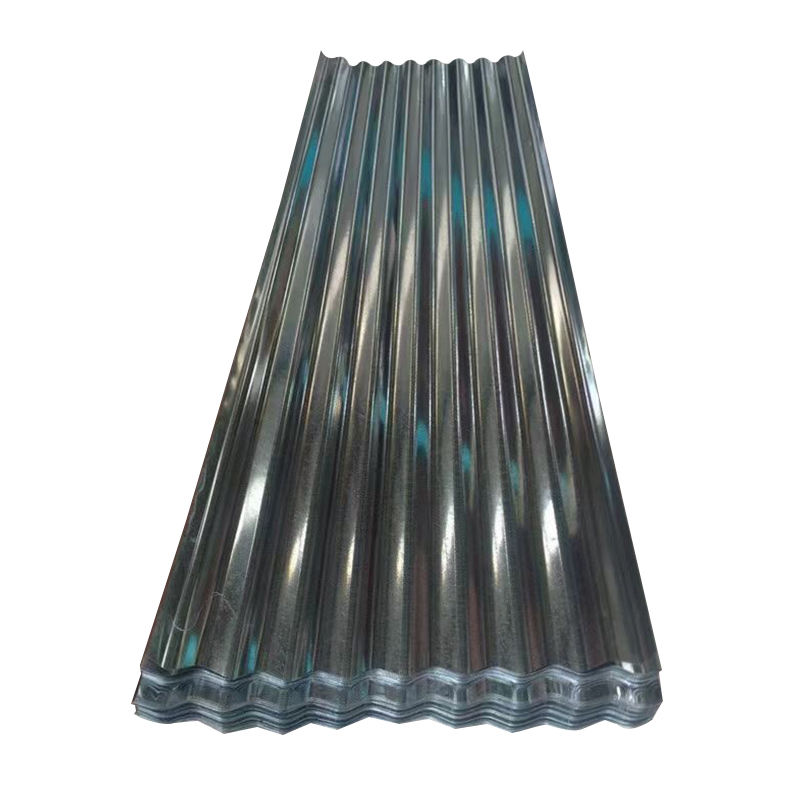

| Surface Type | Printed, embossed, corrugated |