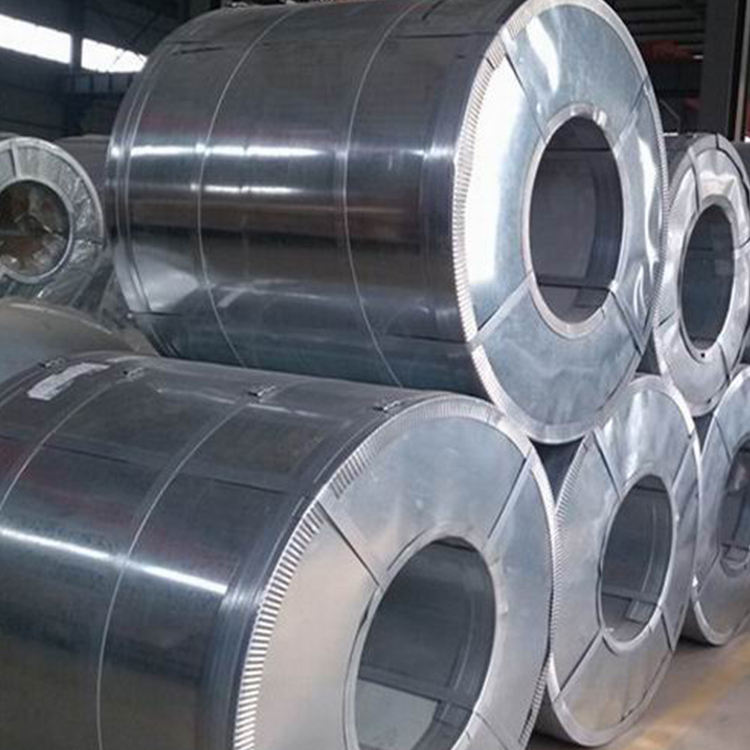

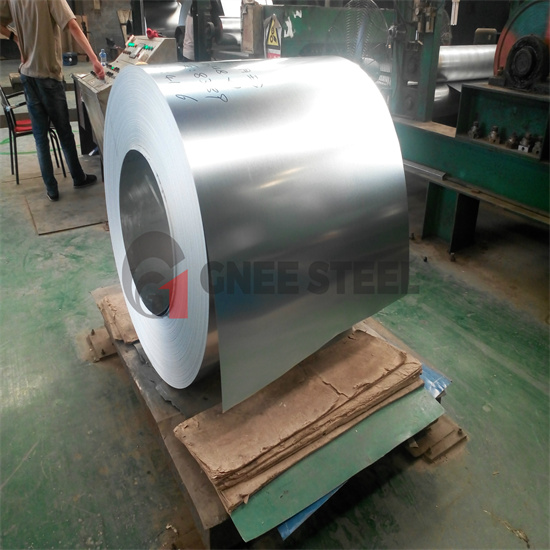

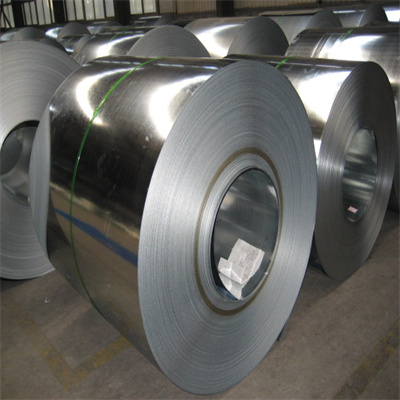

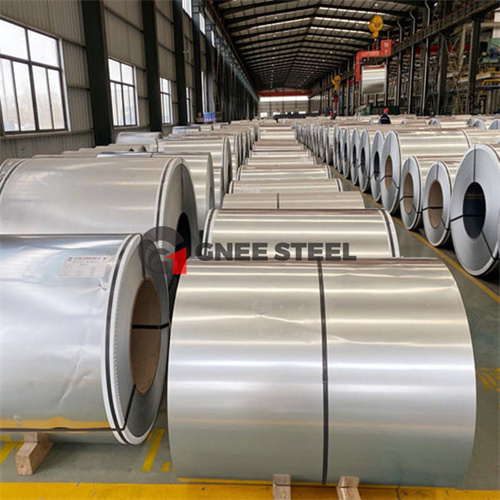

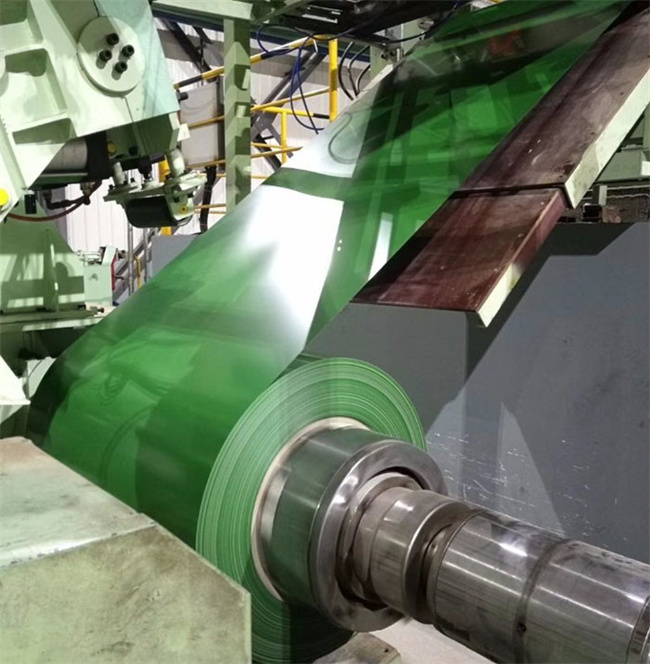

Hot Dipped Galvanized Steel Coils S220GD+ZF

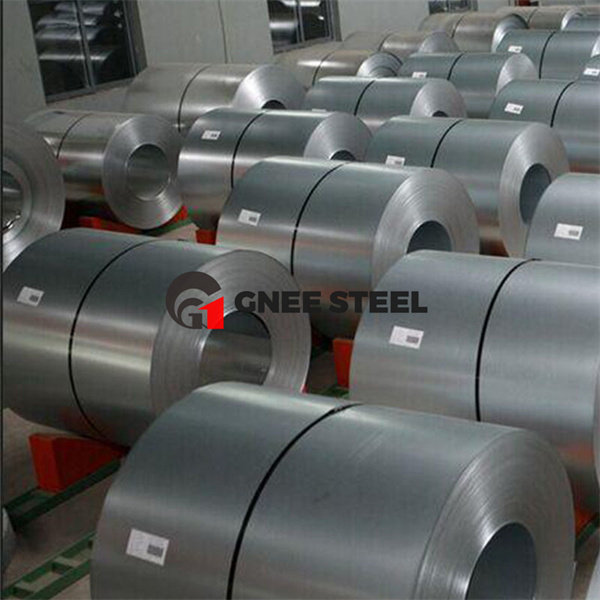

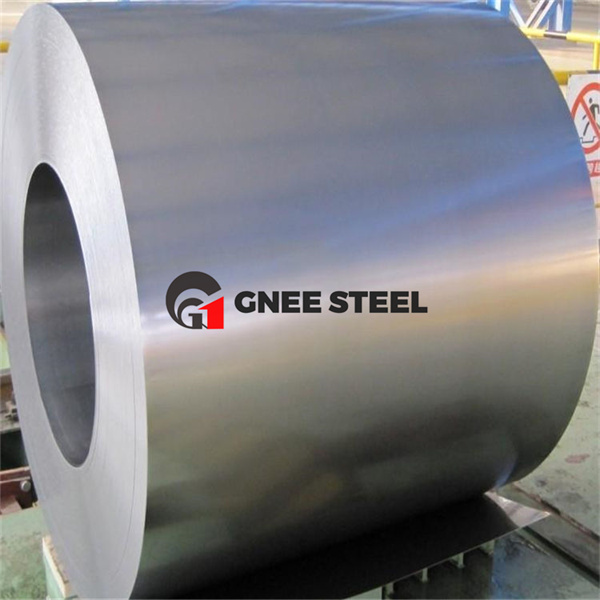

Galvanized coil is a thin steel plate which is immersed in a molten zinc bath to make its surface adhere to a layer of zinc. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in the molten zinc plating bath to make galvanized steel plate; Alloyed galvanized steel sheet.

|

Steel Grade

|

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,

SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

|||

|

Type

|

Galvanized Coil

|

|||

|

Thickness

|

0.12-6.00mm, or customer’s requirement

|

|||

|

Width

|

600mm-1500mm, according to customer’s requirement

|

|||

|

Type of Coating

|

Zinc

|

|||

|

Zinc Coating

|

30-275g/m2

|

|||

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|||

|

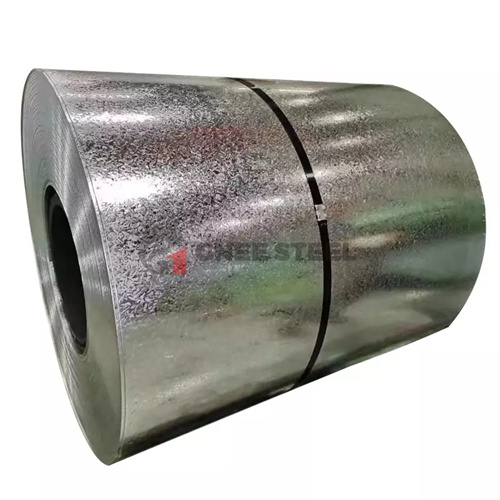

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|||

|

Quality

|

Approved by SGS, ISO

|

|||

Galvanized coil is a thin steel plate which is immersed in a molten zinc bath to make its surface adhere to a layer of zinc. Galvanized coils can be divided into hot-rolled galvanized coils and cold-rolled hot-rolled galvanized coils, which are mainly used in construction, home appliances, automobiles, containers, transportation and household industries. Especially in steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries.

FAQ

1. Q: Can I get samples before order ?

A: Samples can be provided free of charge, and the freight will be paid by the demander.

A: Our delivery time is about one week, timing according to the number of customers.

A: Our usual payment methods are T/T, L/C,payment methods can be negotiated and customized with customers

A: We have obtained ISO, CE and other certifications. From materials to products, we check every process to maintain good quality.