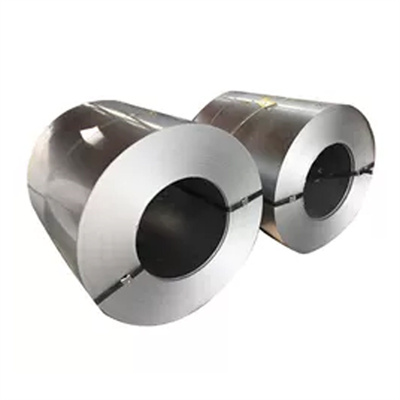

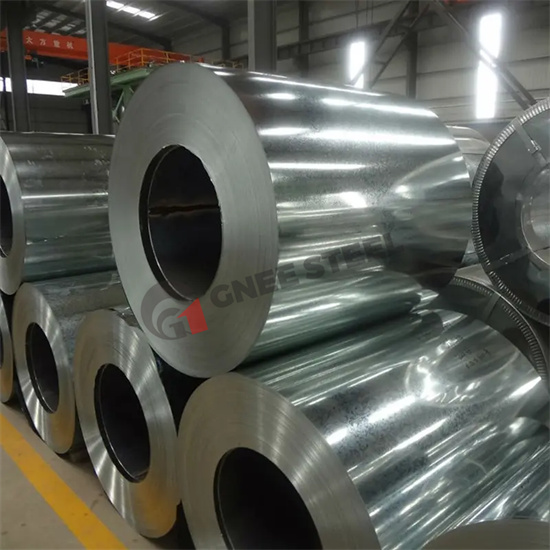

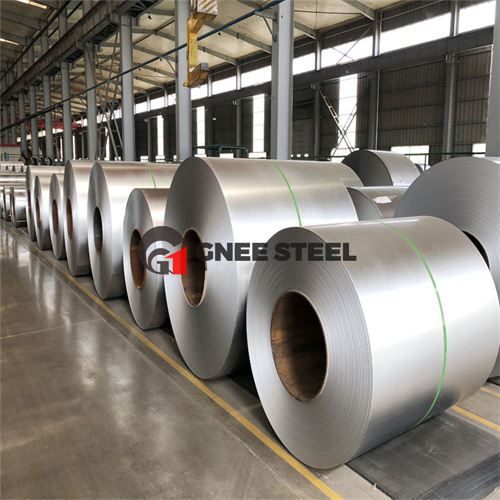

Hot Dipped Galvanized Steel Coil Dx51d Z275g

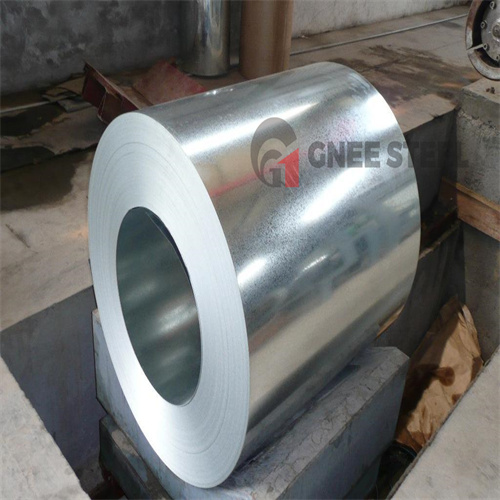

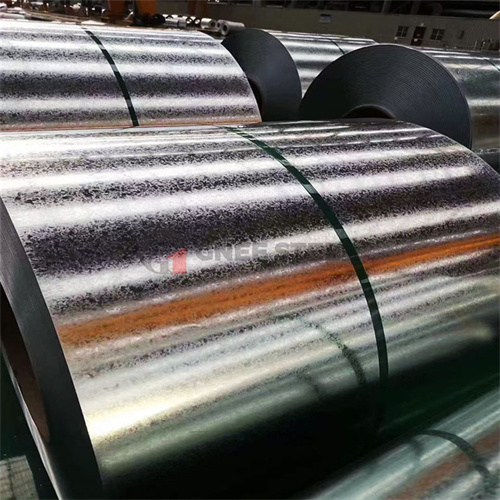

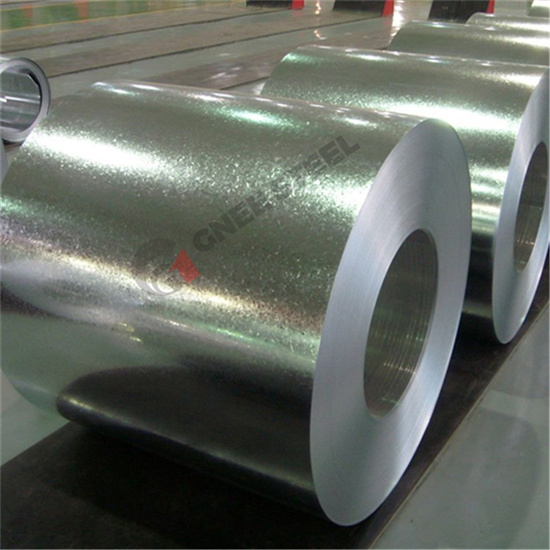

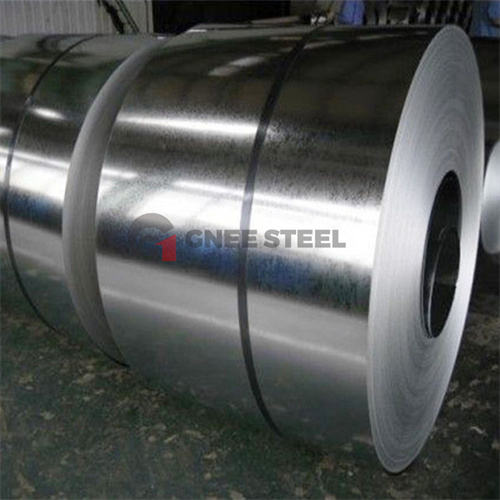

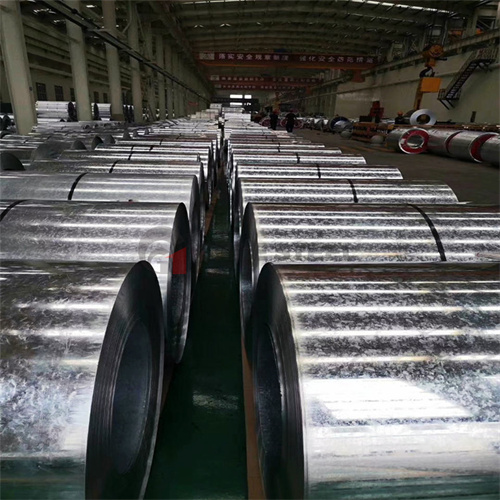

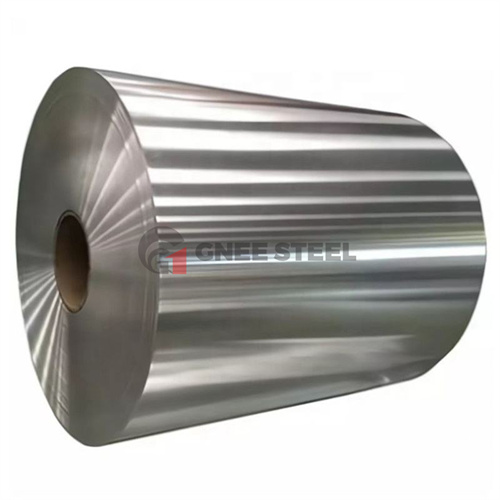

Galvanized coil: dip the steel sheet into the molten zinc bath to make its surface adhere to a layer of zinc. At present, the continuous galvanizing process is mainly used, that is, the rolled steel plate is continuously immersed in the molten zinc plating bath to make galvanized steel plate.

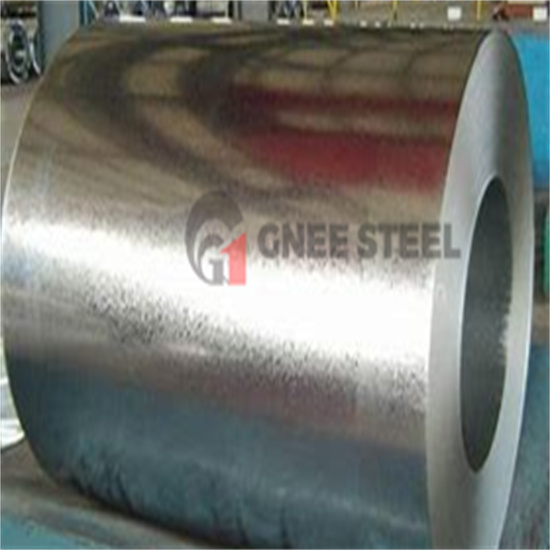

| Process | hot dip galvanized |

| Process Speed | 1#. Max 120m/min, 2#. Max 130m/min |

| Thickness | 1#. 0.25mm upto 1.20mm, 2#. 0.25mm upto 1.0mm |

| Width | 20mm upto 1250mm |

| Surface Finish | zero spangles, skinpassed, oiled,chromated, tension level |

| Coating | zinc layer mass on both sides from 30 g/m2 upto 275g/m2 |

| Yield Strength | 220Mpa upto 750Mpa |

Galvanized steel coil is produced by continuous hot-dip galvanizing process with hot-rolled steel strip or cold-rolled steel strip as the substrate. It is mainly used in construction, household appliances, automobiles, containers, transportation and household industries. Especially in steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries.

FAQ

Q: Can you produce according to samples?

A: Yes, we can customize for customers according to your samples or technical drawings, and we can manufacture molds and fixtures.

Q: How do you ensure product quality?

A: Each product is manufactured by a certified workshop and checked by us one by one according to national QA/QC standards. We can also issue a warranty to the customer to guarantee the quality.

Q: What advantages does your company have?

A (1): High quality and reasonable price.

(2): Rich experience in after-sales service.

(3): Each process has been inspected to ensure the quality of each product.

(4): Professional packaging team to ensure the safety of every package.

(5): Trial orders can be completed within one week.

(6): Samples can be provided upon your request.