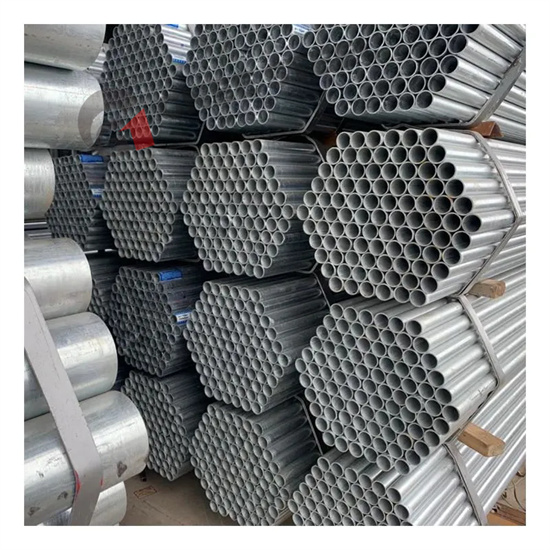

Hot-dip Galvanized Pipe For Greenhouse Steel Structure

Hot-dip galvanized pipes are commonly used in greenhouse steel structures because they offer excellent durability and resistance to corrosion. The process of hot-dip galvanization involves coating steel pipes with a layer of zinc, which helps to protect the steel from rust and other forms of corrosion.

Greenhouse steel structures require pipes that are strong and durable enough to support the weight of the structure, as well as any plants and equipment that may be housed inside. Hot-dip galvanized pipes are able to withstand the elements and provide a long-lasting solution for greenhouse steel structures.

In addition to their strength and durability, hot-dip galvanized pipes are also relatively low-maintenance. They do not require painting or other forms of regular upkeep, which makes them a convenient and cost-effective choice for greenhouse steel structures.

Overall, hot-dip galvanized pipes are an excellent choice for greenhouse steel structures due to their strength, durability, and resistance to corrosion. They provide a reliable and long-lasting solution for supporting the weight of the structure and maintaining a safe and secure environment for plants and equipment.

| STANDARD EMT CONDUIT | ||||||

| Standard | Nominal Size | Outside Diameter | Wall Thickness | Length | ||

| ANSI C 80.3 | inch | inch | mm | mm | feet | mm |

| 1/2″ | 0.706 | 17.93 | 1.07 | 10 | 3050 | |

| 3/4″ | 0.922 | 23.42 | 1.24 | 10 | 3050 | |

| 1″ | 1.163 | 29.54 | 1.45 | 10 | 3050 | |

| 1-1/4″ | 1.510 | 38.35 | 1.65 | 10 | 3050 | |

| 1-1/2″ | 1.740 | 44.20 | 1.65 | 10 | 3050 | |

| 2″ | 2.197 | 55.80 | 1.65 | 10 | 3050 | |

| 2-1/2″ | 2.875 | 73.03 | 1.83 | 10 | 3050 | |

| 3″ | 3.500 | 88.90 | 1.83 | 10 | 3050 | |

| 3-1/2″ | 4.000 | 101.60 | 2.11 | 10 | 3050 | |

| 4″ | 4.500 | 114.30 | 2.11 | 10 | 3050 | |

Product Quality

We have implemented excellent quality control in every detail and provide you with every type of high-quality service.

1: Strictly select high-quality aluminum raw materials that meet the standards, and forge high-quality products with high-quality materials.

2: Strictly control the production and manufacturing process of GNEE product aluminum coils. Don’t treat small things as actions to achieve true quality control.