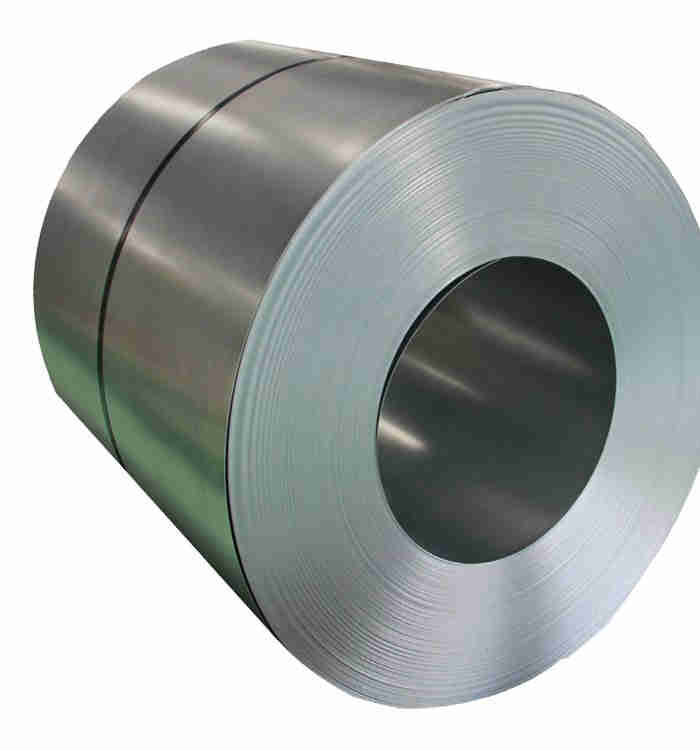

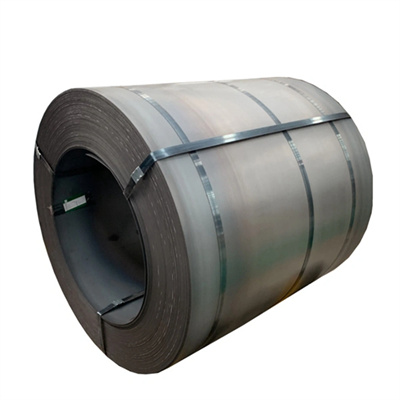

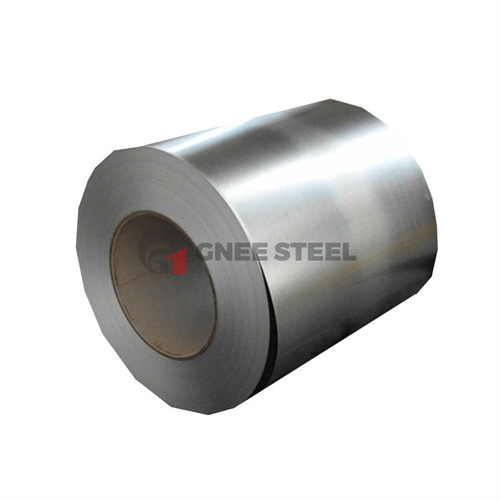

Home » Cold Rolled Steel Coil » GI/SECC DX51 ZINC coated Cold rolled galvanized steel coil

Content

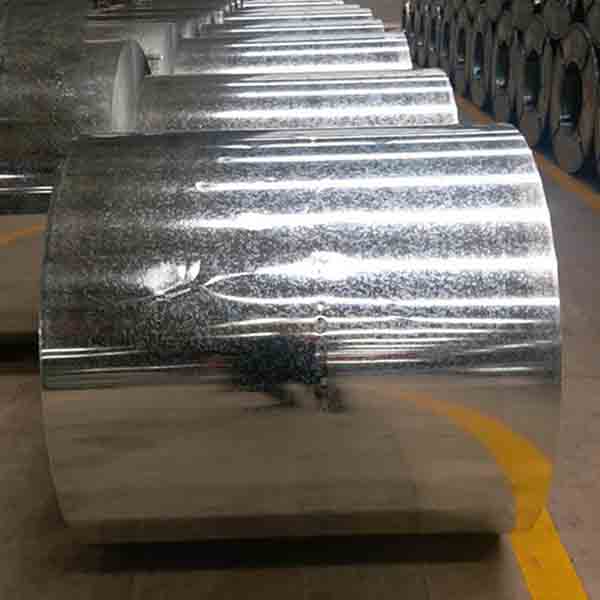

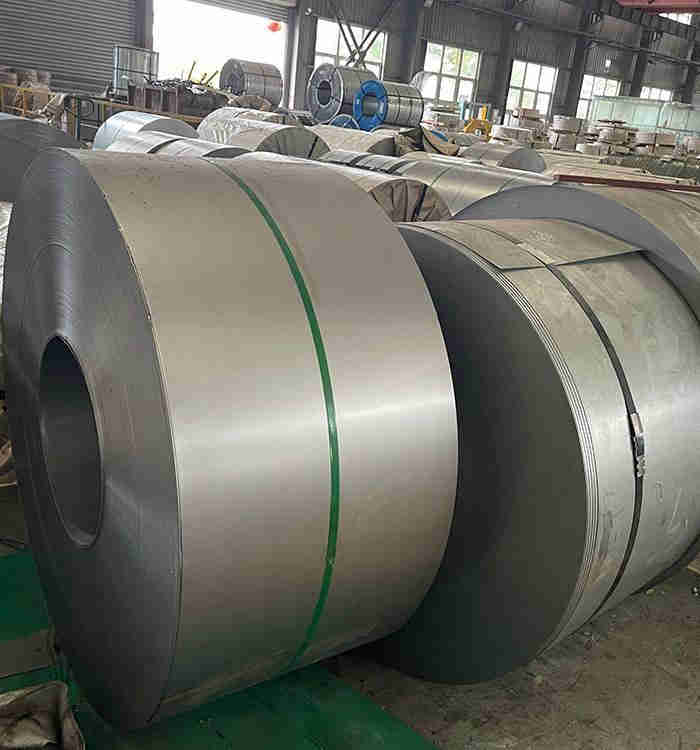

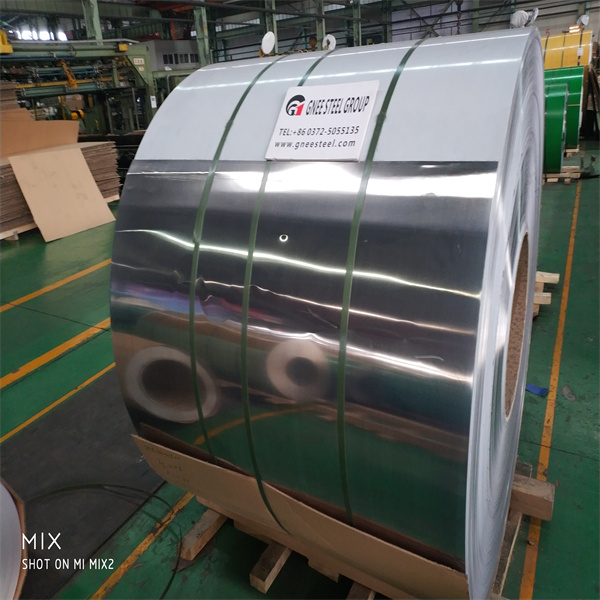

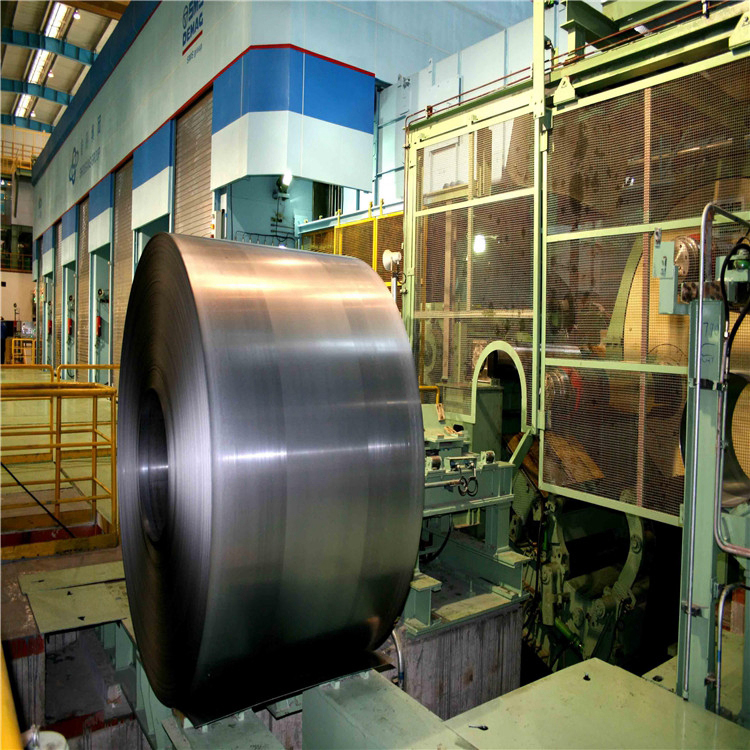

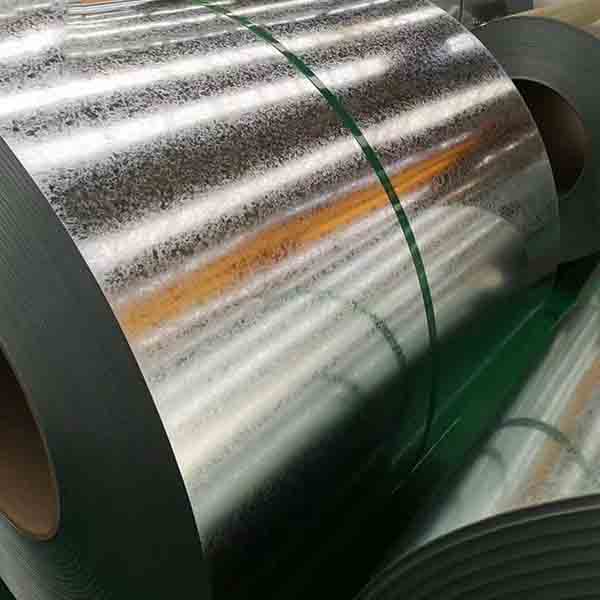

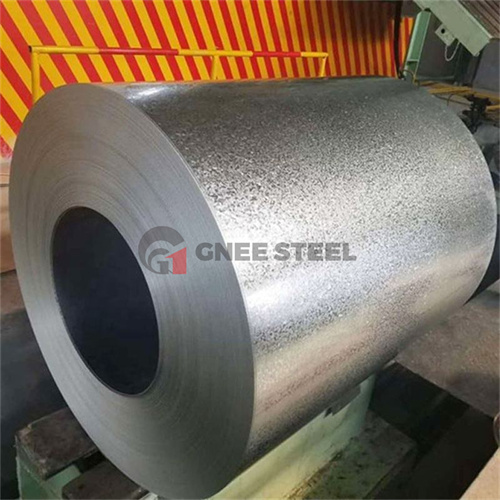

Galvanized Steel Sheet in Coil (GI) is produced by passing the Full Hard sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc’s characteristics. Usually, hot-dipped galvanized steel sheet and galvanized steel coil process and specifications are basically the same.Galvanizing is the process of applying a protective zinc coating to a steel sheet or iron sheet, to prevent rusting.

|

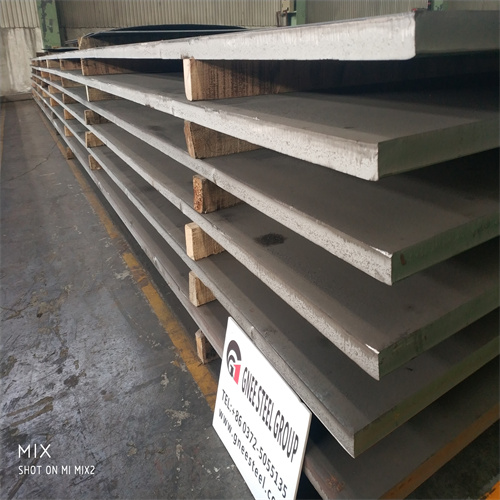

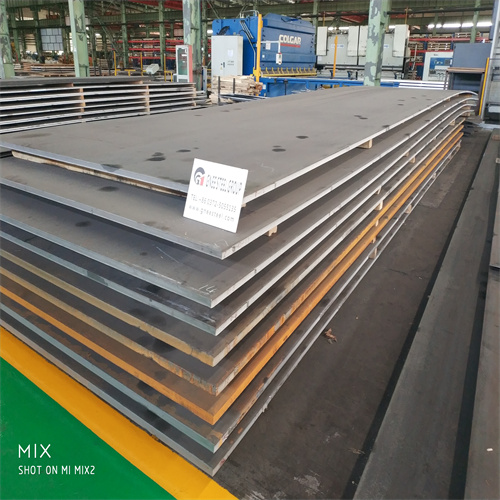

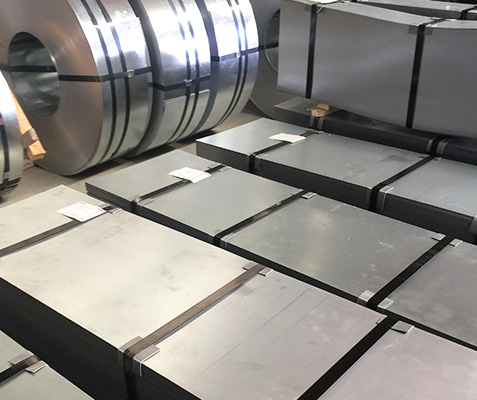

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.12-6.00mm,or customer’s requirement

|

|

Width

|

600mm-1500mm, according to customer’s requirement

|

|

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI) And Cold Dipped Galvanized Steel(CDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

Coil Weight

|

3-20 metric ton per coil

|

|

Package

|

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by

seven steel belt.or according to customer’s requirement |

Inquiry

More Cold Rolled Steel Coil