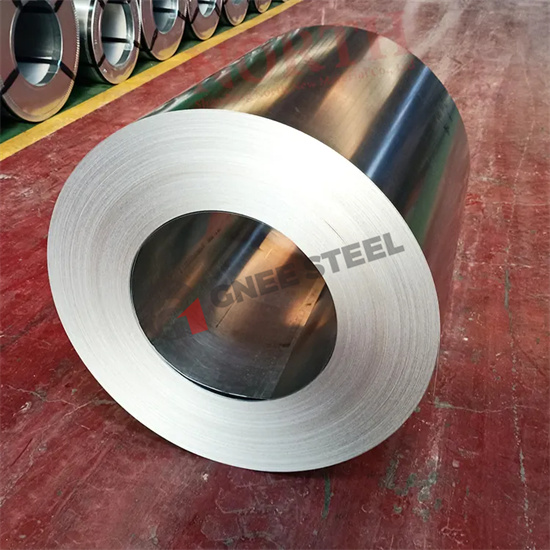

Galvanized wire for manufacturing nails

The manufacturing process for galvanized nails typically involves feeding the galvanized wire into a nail-making machine. The machine cuts the wire to the desired length and then shapes it into the appropriate nail shape using a series of dies.

Once the nails are formed, they are typically cleaned and polished to remove any sharp edges or burrs. The finished nails are then sorted and packaged for shipment to customers.

Galvanized wire is also used for other types of fasteners, such as screws and staples, as well as in a variety of other applications, including fencing, construction, and automotive manufacturing.

|

Steel Grade

|

high carbon steel

|

|

Standard

|

GB

|

|

Place of Origin

|

Shandong China

|

|

Type

|

galvanized

|

|

Application

|

Construction

|

|

Alloy Or Not

|

Non-Alloy

|

|

Special Use

|

Free Cutting Steel

|

|

Model Number

|

SAE1040 SAE1045 SAE1070 SAE1080

|

|

Brand Name

|

Zhongshen

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, Welding, Punching, Decoiling, Cutting

|

|

Grade

|

high carbon steel

|

|

Delivery Time

|

8-14 days

|

|

Product name

|

Steel Wire Rope

|

|

Surface

|

Galvanised

|

|

Packing

|

Standard Seaworthy Packing

|

|

Certificate

|

ISO9001

|

FAQ

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

Q: How is your Payment Term?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q: Can you provide sample?

A: Yes, for regular sizes sample is free but buyer need to pay freight cost.