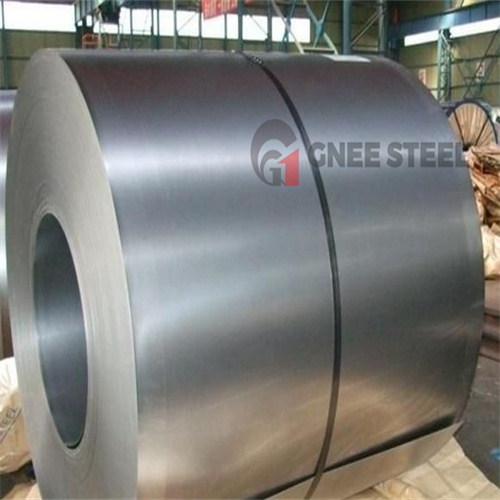

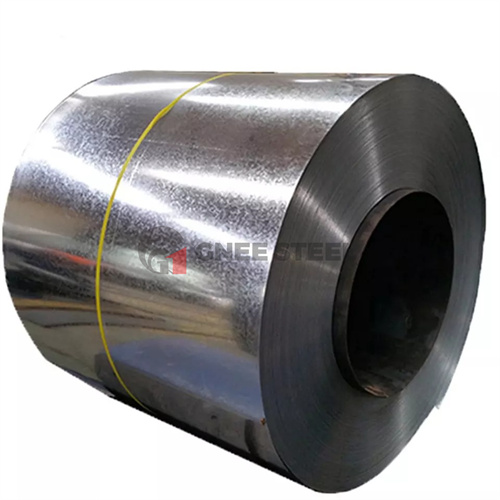

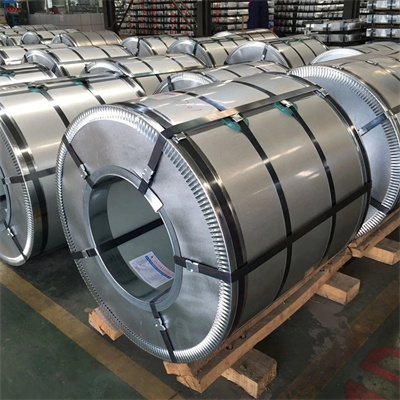

Galvanized steel coils excel in corrosive environments

Galvanized steel coils are known for their excellent corrosion resistance, which is one of the key reasons why they are widely used in a range of applications. This makes galvanized steel coils ideal for use in harsh environments, where they are exposed to moisture, salt, and other corrosive elements.

| Product Name | Specifications |

|---|---|

| Galvanized Steel Sheets | Thickness: 0.12-4.0 mm; Width: 600-1500 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Coils | Thickness: 0.12-4.0 mm; Width: 600-1500 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Strips | Thickness: 0.12-4.0 mm; Width: 30-600 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Tubes | Outer Diameter: 15-165 mm; Wall Thickness: 0.6-2.5 mm; Zinc Coating: 60-275 g/m2 |

| Galvanized Steel Wire | Diameter: 0.8-6.0 mm; Zinc Coating: 60-275 g/m2 |

General Information:

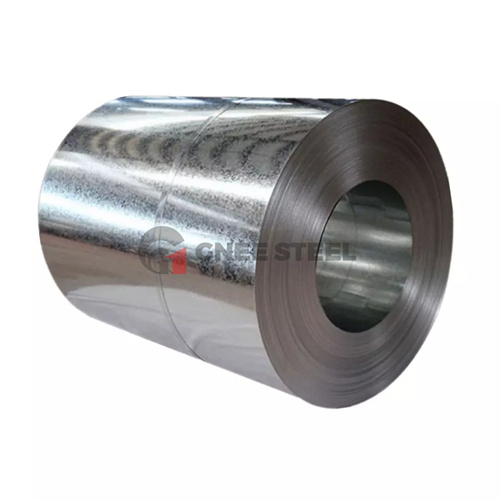

Galvanized steel coils are made by hot-dip galvanizing, which involves immersing the steel in a bath of molten zinc. This creates a metallurgical bond between the zinc and steel, which provides a barrier against corrosion and other forms of damage. The thickness of the zinc coating can vary, depending on the application and the level of protection required. Galvanized steel coils are widely used in construction, automotive, and other industries due to their excellent corrosion resistance and durability.

Corrosion Resistance:

Galvanized steel coils are highly resistant to corrosion, even in harsh environments. The zinc coating provides a barrier against moisture, salt, and other corrosive elements, which can cause rust and other forms of damage to unprotected steel. Galvanized steel coils are ideal for use in outdoor applications, such as roofing, fencing, and signage, where they are exposed to the elements. They are also used in automotive applications, where they are exposed to salt and other corrosive substances on the road.

In summary, galvanized steel coils provide excellent corrosion resistance, making them ideal for use in harsh environments and a range of applications. The thickness of the zinc coating can vary, depending on the level of protection required, and galvanized steel coils are widely used in construction, automotive, and other industries due to their strength, durability, and resistance to corrosion.