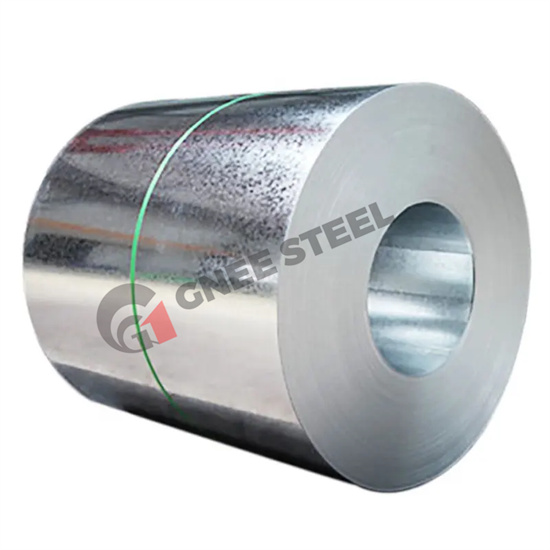

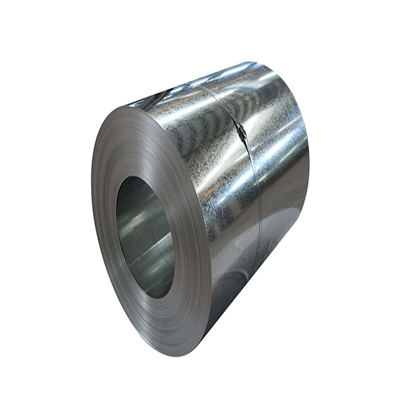

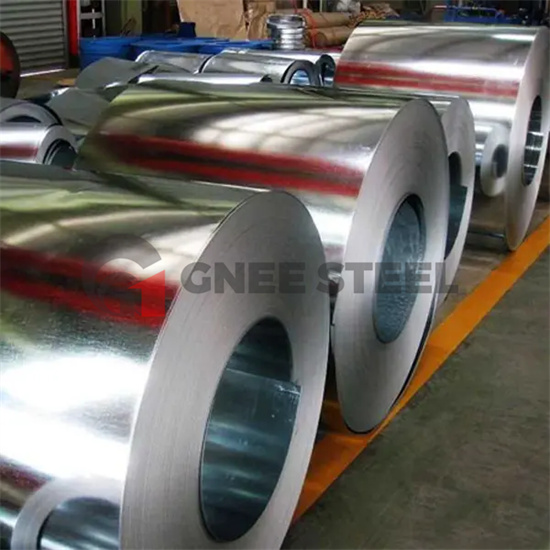

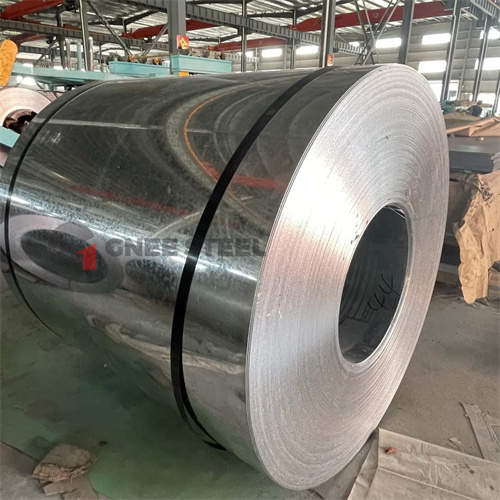

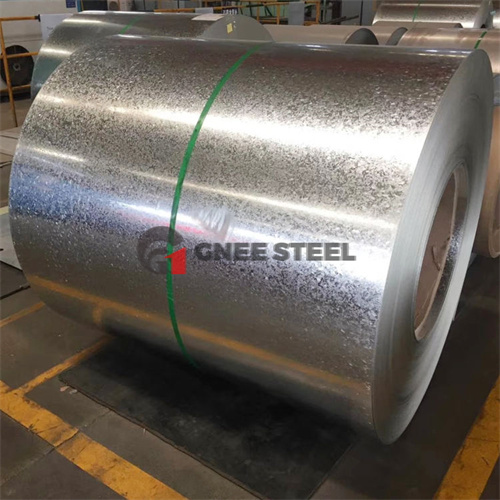

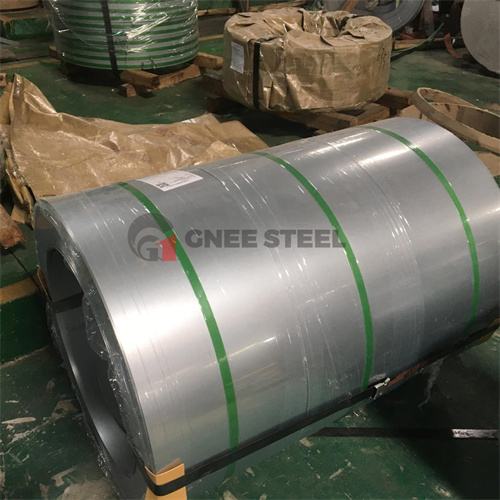

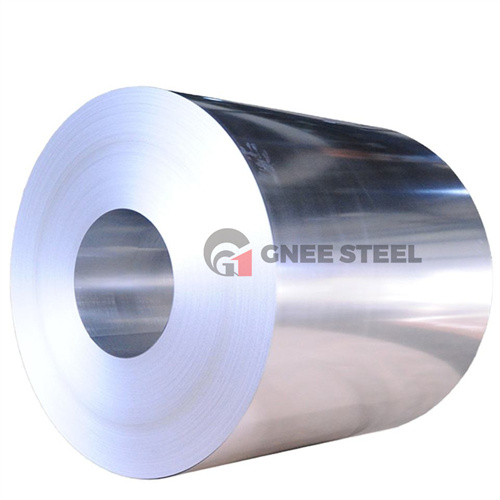

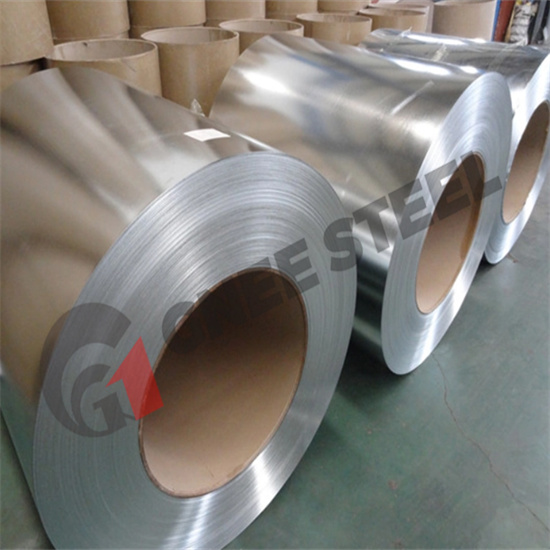

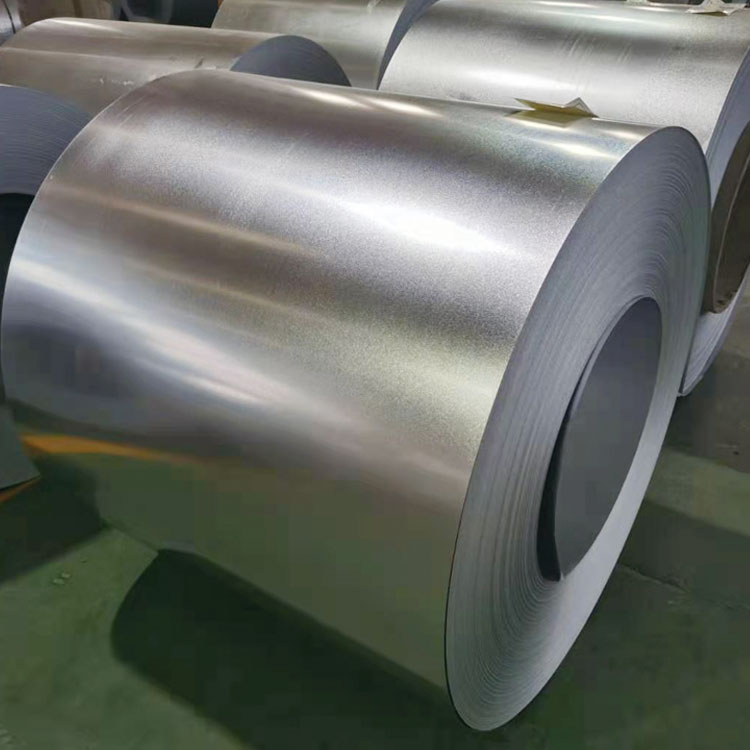

galvanized Steel Coil H420lad

The main raw material of galvanized coil is zinc alloy, and its production process is continuous galvanizing. The advantages of galvanized coil are good adhesion and weldability. Its disadvantages include exposed steel, inclusion, mechanical damage, etc., which is mainly caused by surface oxidation.

|

Thickness

|

0.13-3.0mm

|

|

Width

|

Galvanized steel strip:24-600 mm; galvanized steel coil:600-1250mm

|

|

Coil weight

|

Usually is 3-4.5 tons,the max coil is 10 tons

|

|

Zn coating

|

0.13-0.8 mm is 30-150 g/m2; 0.8-1.5 mm is 30-180 g/m2;1.5-6.0 mm is 30-275 g/m2

|

|

Coil ID

|

600-1500 mm,Normal width is 91 4/1000/1219/1250/1500 mm

|

|

Steel grade

|

DX51D,DX52D,DC01,DC02,SGHC

|

Zinc coil, which immerses the steel sheet into the molten zinc bath to make its surface adhere to a layer of zinc. At present, it is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in the molten zinc plating bath to make galvanized steel plate; Alloyed galvanized steel sheet. This kind of steel plate is also made by hot-dip method, but it is heated to about 500 ℃ immediately after it is out of the tank, so that it forms an alloy coating of zinc and iron. The galvanized coil has good coating adhesion and weldability.

FAQ

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

Q: How is your Payment Term?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Our Email: info@gescosteel.com.