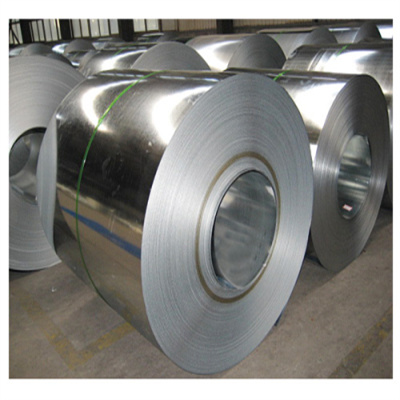

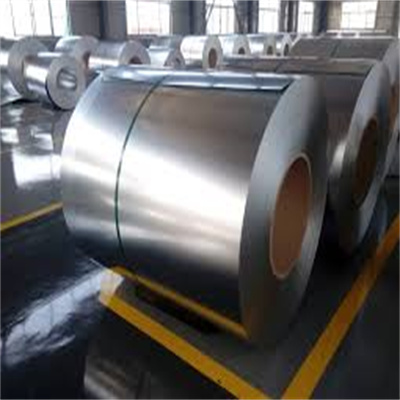

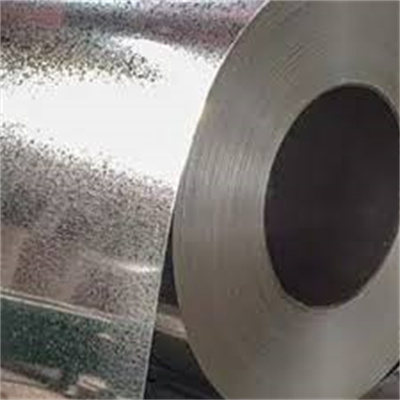

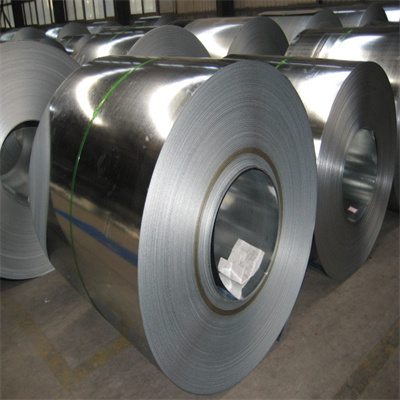

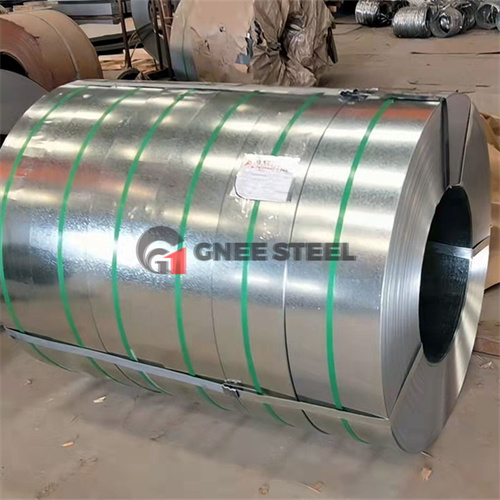

galvanized steel coil DX51D z60

Galvanized coil, dip a sheet steel plate into a melted zinc tank, so that the surface adhesion of a zinc sheet steel.

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade

|

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement

|

|

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.12-6.00mm,or customer’s requirement

|

|

Width

|

600mm-1500mm, according to customer’s requirement

|

|

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

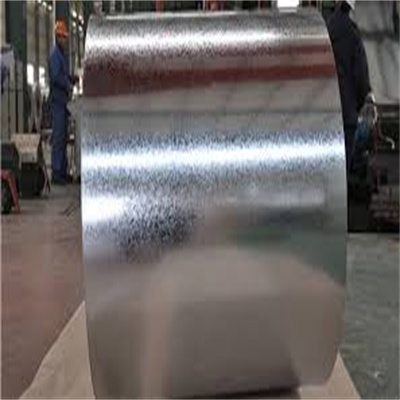

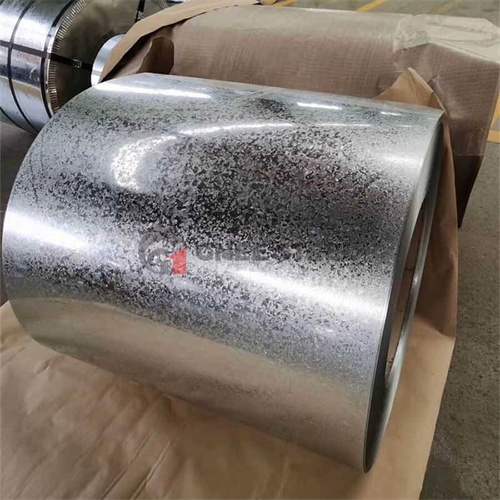

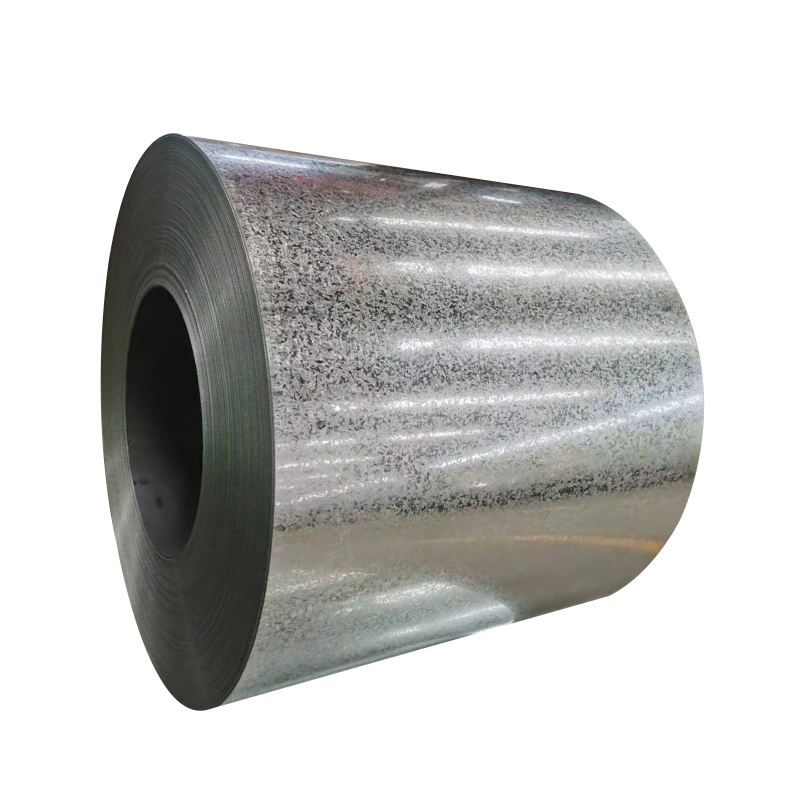

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

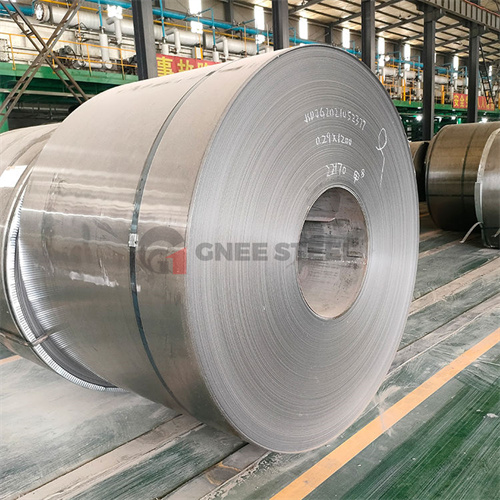

ID

|

508mm/610mm

|

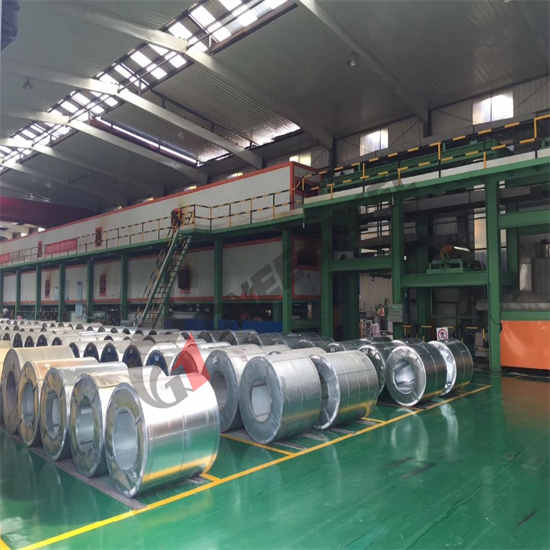

Galvanised coils are mainly produced using a continuous galvanising process, whereby coils of steel are continuously dipped in a bath of molten zinc to make galvanised steel; alloyed galvanised steel. This steel is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to around 500°C to produce an alloyed coating of zinc and iron. This type of galvanised coil has good paint adhesion and weldability.

FAQ

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Our Email: info@gescosteel.com.