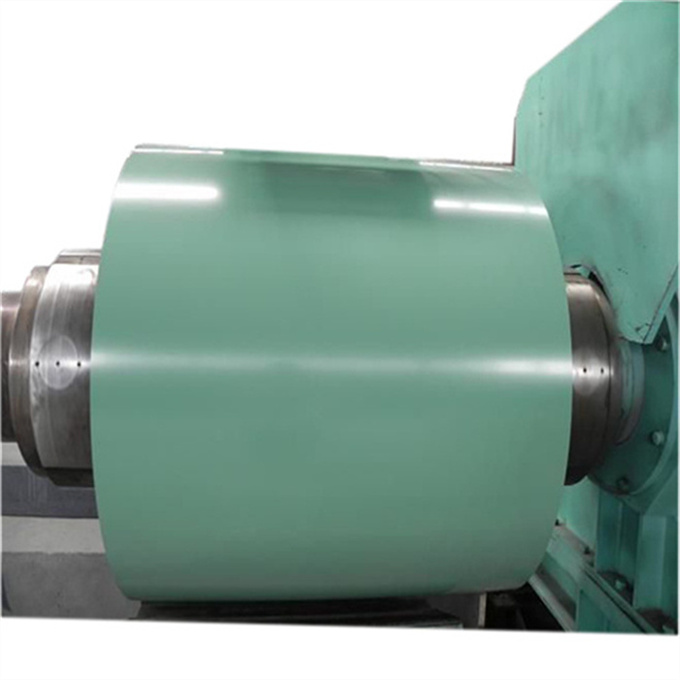

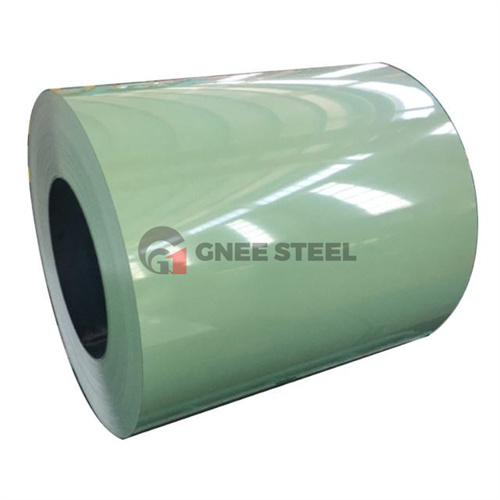

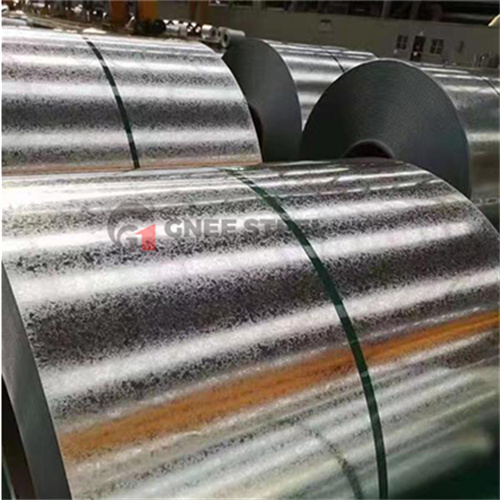

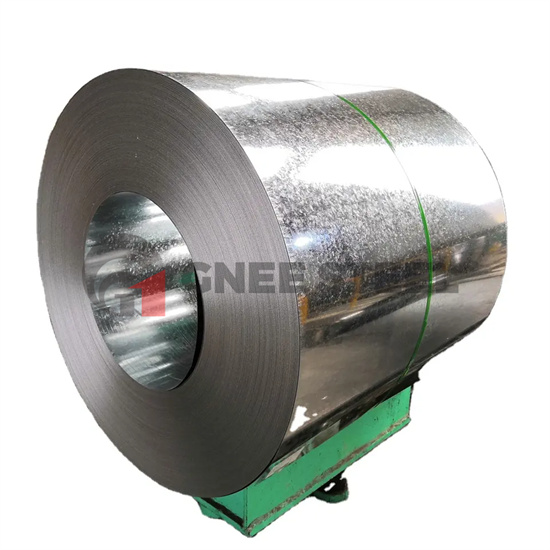

Galvanized High Speed Cold Rolled Steel Coil

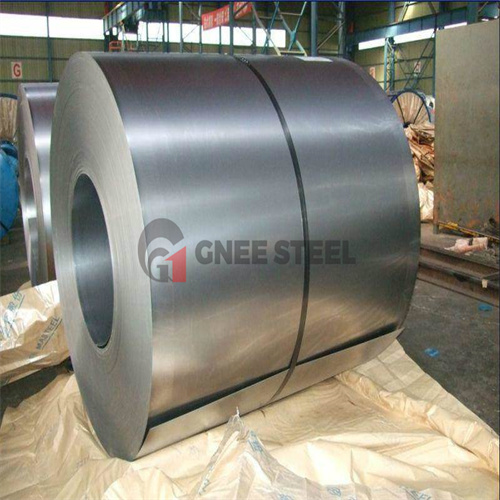

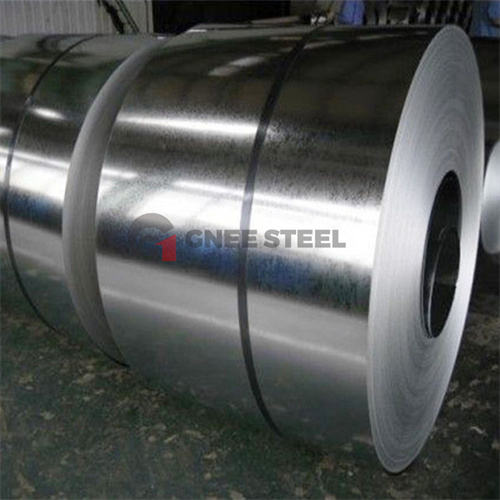

The galvanizing process involves immersing the steel coil in a bath of molten zinc, which creates a protective layer on the surface of the steel. The zinc layer provides excellent corrosion resistance, which makes galvanized high-speed cold rolled steel coils ideal for use in harsh environments.

The high-speed cold rolling process involves passing the steel coil through a series of rollers at high speeds, which helps to refine the structure of the steel and improve its strength and durability. This process also results in a smooth, polished surface that is ideal for applications that require a high-quality finish.

| Advantage | Description |

|---|---|

| High strength | The high-speed cold rolling process makes the steel stronger and more durable. |

| Corrosion resistance | The galvanizing process provides excellent resistance to corrosion. |

| Smooth surface | The high-speed cold rolling process produces a smooth surface, making it suitable for applications that require a high-quality finish. |

| Long lifespan | Both the galvanizing and high-speed cold rolling processes can increase the durability and lifespan of the steel. |

| Wide range of applications | Can be used in various applications, including automotive parts, construction materials, electrical enclosures, and consumer goods. |

FAQ

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: How long is your delivery time?

A: For Stocks, we can send the goods to loading port within 7 days after receiving the deposit ;

For production period, it usually needs about 15 days ~30 days after receiving the deposit.

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.