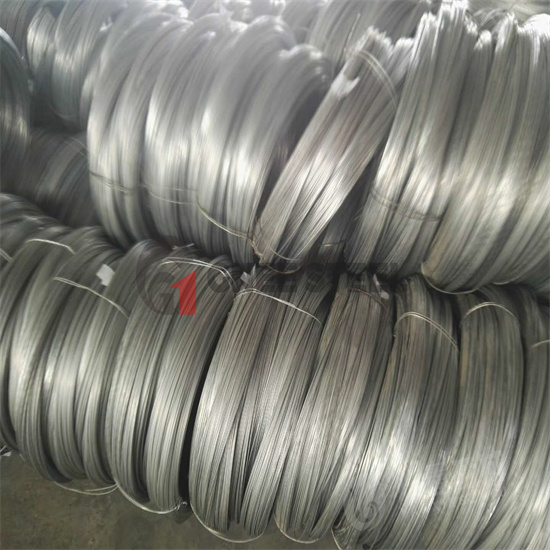

Galvanized Aluminum Alloy Wire

The galvanization process involves coating the aluminum alloy wire with a layer of zinc, which helps to prevent rust and corrosion. This coating can provide long-lasting protection against environmental factors such as moisture and salt.

Galvanized aluminum alloy wire comes in a variety of sizes and can be customized to meet the specific needs of different applications. It is commonly used in electrical wiring applications, such as in overhead power lines and electrical transmission towers, as well as in construction applications, such as in the production of fences, mesh, and other products. Due to its lightweight and durable nature, galvanized aluminum alloy wire is also commonly used in the production of automotive and aerospace components.

| Specification | Diameter (mm) | Zinc Coating Weight (g/m²) | Tensile Strength (MPa) |

|---|---|---|---|

| 1.2 | 20 | 100 | 280-380 |

| 1.5 | 25 | 120 | 280-380 |

| 1.8 | 30 | 150 | 280-380 |

| 2.0 | 35 | 180 | 280-380 |

| 2.5 | 45 | 200 | 280-380 |

| 3.0 | 55 | 220 | 280-380 |

The main advantages of GNEE Company are:

- Professional steel suppliers: GNEE has professional steel suppliers who can provide high-quality steel products;

- Global sales network: GNEE Company has a perfect sales network in the world, which can meet the needs of customers;

- Professional technical support: GNEE company has a professional technical support team, can provide professional technical support for customers;

- Excellent service: GNEE Company has excellent service team, can provide customers with excellent service.