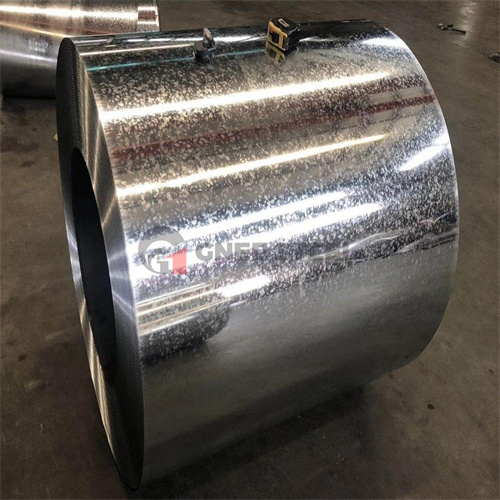

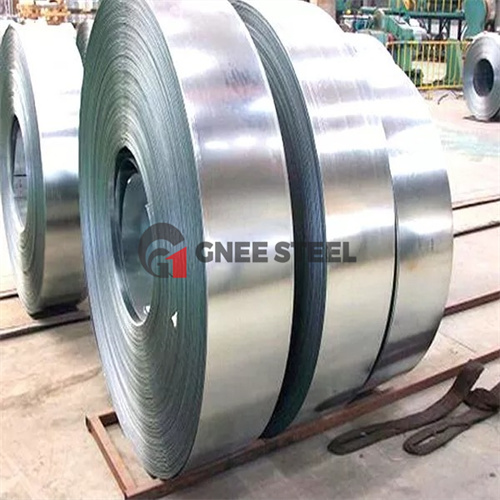

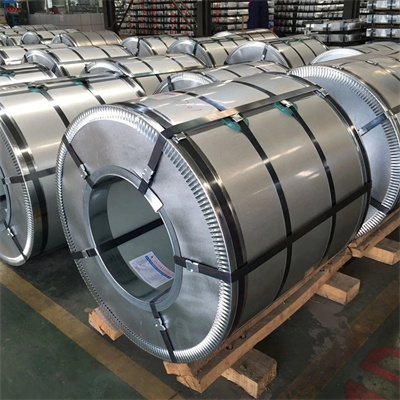

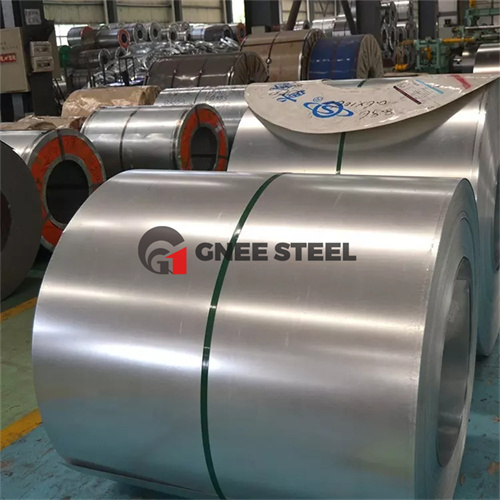

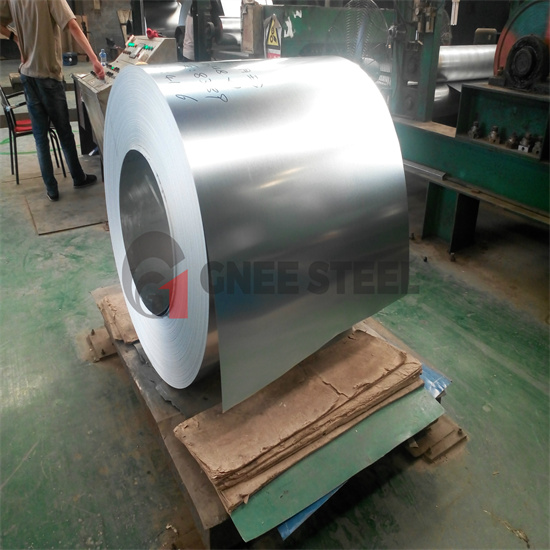

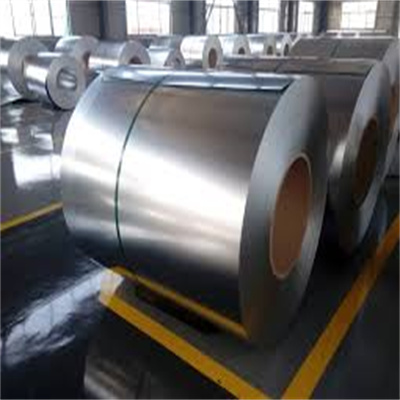

DX51D SGCC coating cold rolled galvanized steel coil

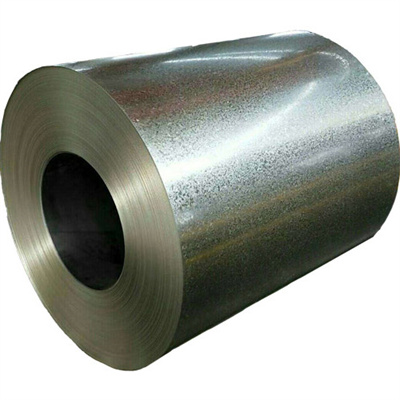

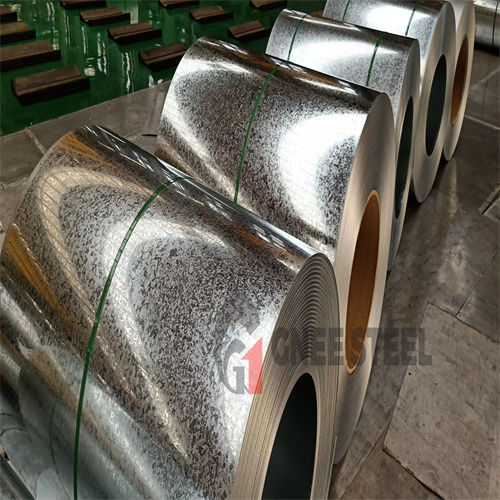

Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.

|

Thickness

|

0.13-3.0mm

|

|

Width

|

Galvanized steel strip:24-600 mm; galvanized steel coil:600-1250mm

|

|

Coil weight

|

Usually is 3-4.5 tons,the max coil is 10 tons

|

|

Zn coating

|

0.13-0.8 mm is 30-150 g/m2; 0.8-1.5 mm is 30-180 g/m2;1.5-6.0 mm is 30-275 g/m2

|

|

Coil ID

|

600-1500 mm,Normal width is 91 4/1000/1219/1250/1500 mm

|

|

Steel grade

|

DX51D,DX52D,DC01,DC02,SGHC

|

|

Surface

|

regular/mini/big/zero spangle,skin pass, chromated, unoiled, dry

|

|

Packaging

|

seaworthy export standard package, or according to the customers’requirement

|

|

Delivery time

|

With 15 –25 days after receipt of deposit or L/C

|

|

Market

|

North/South America, Europe, Asia,Africa,Mid East

|

|

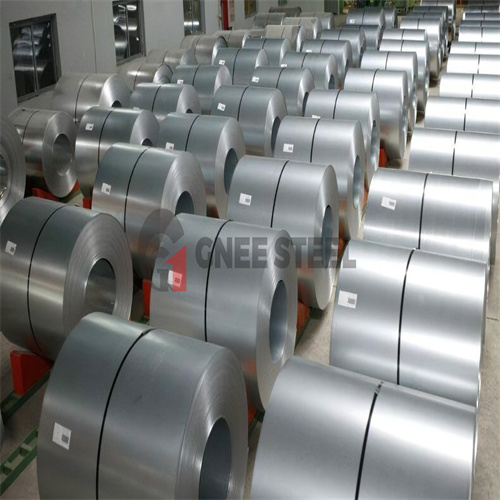

Productivity

|

2000 Metric ton /month

|

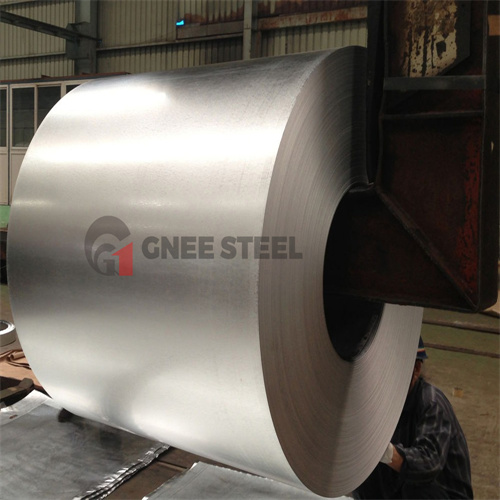

Product Advantages

01.Anticorrosive:13 years in heavy industrial areas,50 years in the ocean,104 years in the suburbs and 30 years in cities.

02.Cheap:The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable:The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

If you are interested in our products, please feel free to send us an email to inquire.

Our Email: info@gescosteel.com.