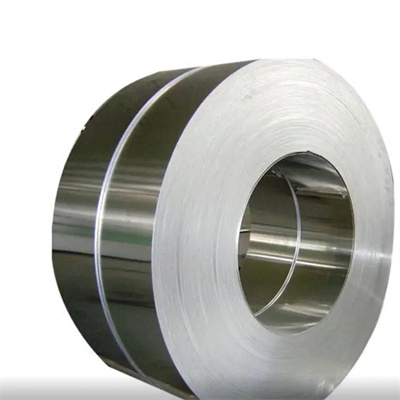

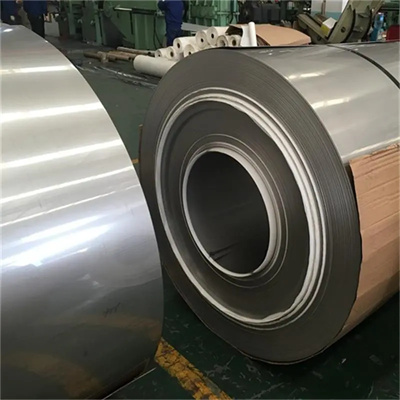

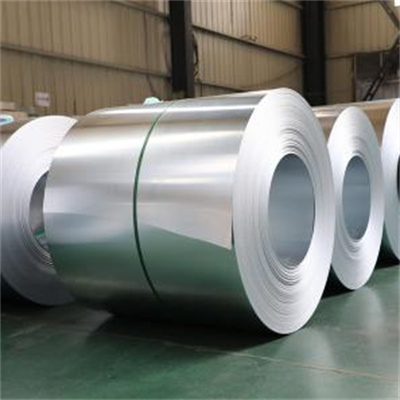

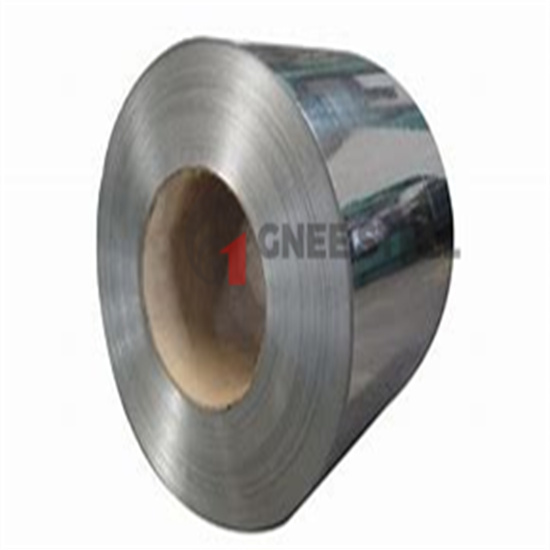

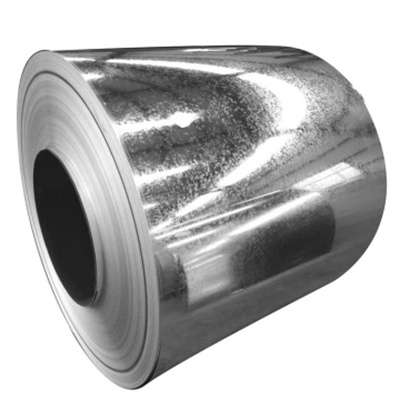

Cold Rolled/hot Dipped Galvanized Steel Coil

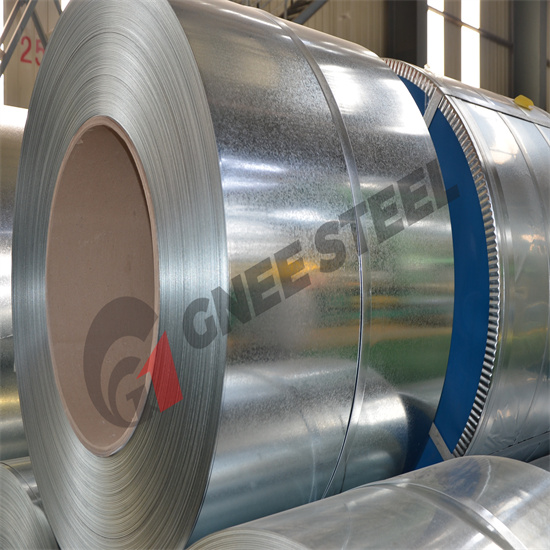

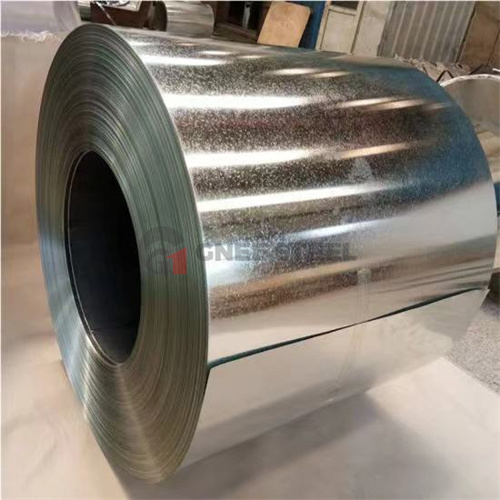

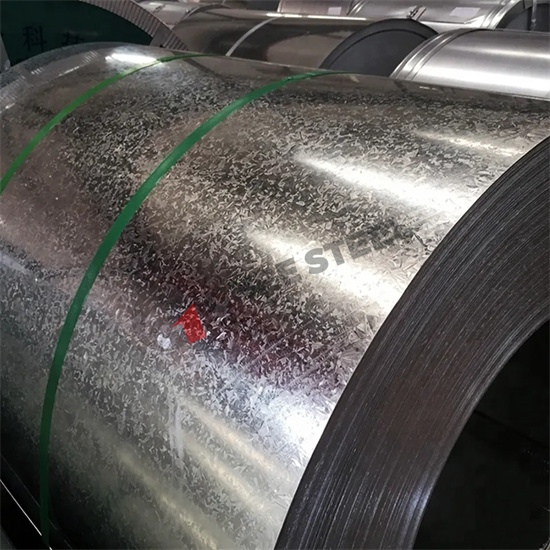

Hot-dip galvanized steel coils are produced by cold-rolled steel coils in a zinc bath at a temperature of approximately 460 degrees Celsius. The zinc coating on the steel coil substrate acts as a barrier between the atmosphere and the metal surface. In addition, due to its low chemical potential compared to iron (Fe), it is attacked and dissolved first, thus providing superior corrosion resistance (cathodic protection).

Product Description:

|

Thickness

|

0.13-3.0mm

|

|

Width

|

Galvanized steel strip:24-600 mm; galvanized steel coil:600-1250mm

|

|

Coil weight

|

Usually is 3-4.5 tons,the max coil is 10 tons

|

|

Zn coating

|

0.13-0.8 mm is 30-150 g/m2; 0.8-1.5 mm is 30-180 g/m2;1.5-6.0 mm is 30-275 g/m2

|

|

Coil ID

|

600-1500 mm,Normal width is 91 4/1000/1219/1250/1500 mm

|

|

Steel grade

|

DX51D,DX52D,DC01,DC02,SGHC

|

|

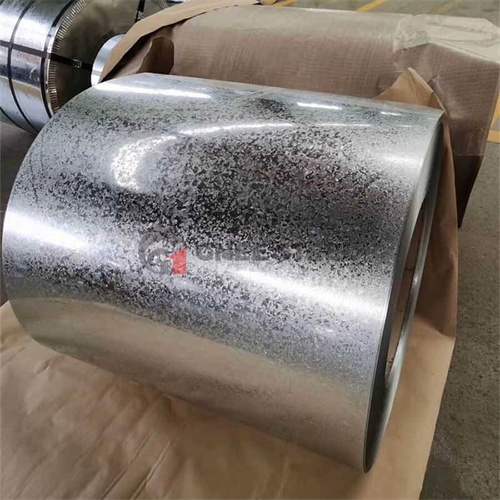

Surface

|

regular/mini/big/zero spangle,skin pass, chromated, unoiled, dry

|

|

Packaging

|

seaworthy export standard package, or according to the customers’requirement

|

|

MOQ

|

1 ton , We can accept sample order.

|

|

Shipment Time

|

Within 15-20 workdays after receiving deposit or L/C

|

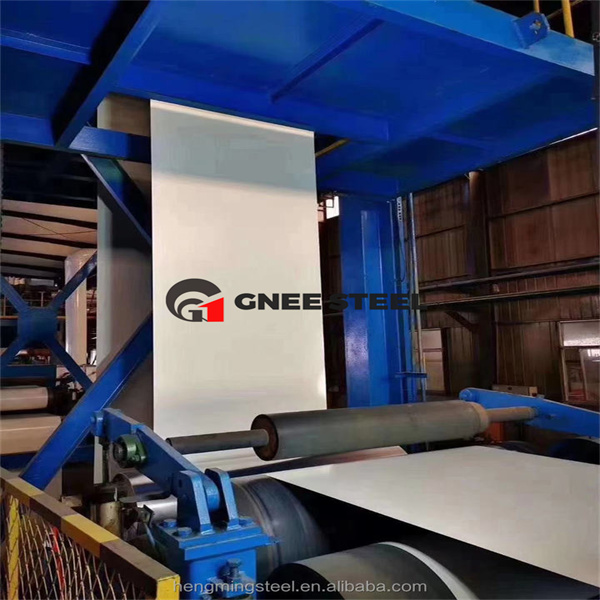

GNEE’s five commitments:

1. Quality: Strictly control the quality from three levels. In the first stage, quality testing is carried out on the production line. The second level, incoming quality inspection. Third stage, quality test before loading.

2. Timeliness :24 hours online. At any time to provide customers with consultation and quotation services.

3. Accuracy: Strictly comply with customer standards to ensure tolerance range and meet customer requirements.

4. Integrity: If customers complain about product quality problems, our company will actively cooperate to solve the problem. If it is our company’s responsibility, we will bear the corresponding responsibility and compensation.

5. Integrity: Establish good long-term relationship with customers.