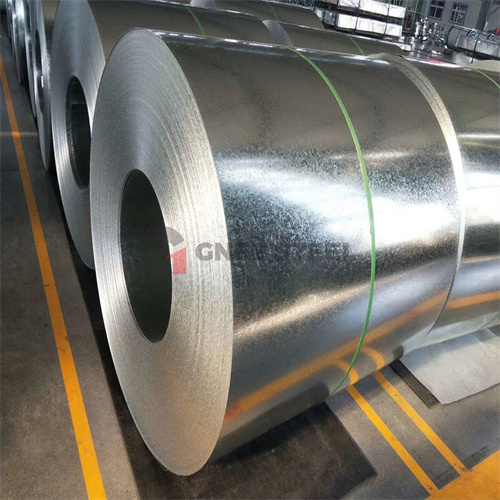

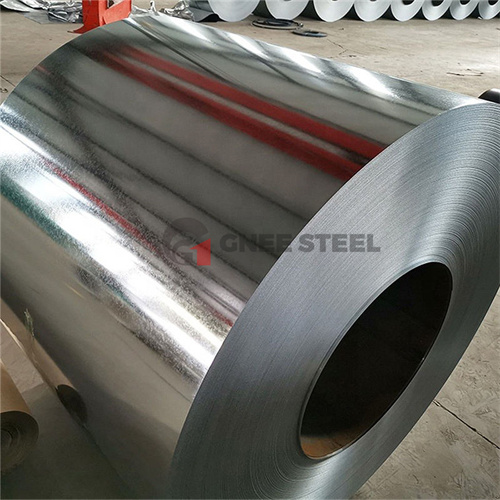

ASTM DX51D Galvanized Steel Coil

Galvanized steel coil is a steel plate with a layer of zinc on its surface. Galvanizing is often used as an economical and effective rust prevention method. About half of the world’s zinc production is used in this process.

|

SIZE

|

Zinc coating

|

Material

|

|

0.20*1000*C

|

80

|

DX51D+Z

|

|

0.25*1000*C

|

80

|

DX51D+Z

|

|

0.3*1000*C

|

80

|

DX51D+Z

|

|

0.35*1000*C

|

80

|

DX51D+Z

|

|

0.4*1000*C

|

80

|

DX51D+Z

|

|

0.5*1000*C

|

80

|

S280GD+Z

|

|

0.5*1000*C

|

80

|

DX51D+Z

|

|

0.58*1000*C

|

80

|

S350GD+Z

|

|

0.6*1000*C

|

80

|

DX51D+Z

|

|

0.7*1000*C

|

80

|

DX51D+Z

|

|

0.75*1000*C

|

80

|

DX51D+Z

|

|

0.8*1000*C

|

80

|

DX51D+Z

|

|

0.8*1000*C

|

80

|

DX53D+Z

|

|

0.85*1000*C

|

80

|

DX51D+Z

|

|

0.9*1000*C

|

80

|

DX51D+Z

|

|

0.98*1000*C

|

80

|

DX51D+Z

|

|

0.95*1000*C

|

80

|

DX51D+Z

|

|

1.0*1000*C

|

80

|

DX51D+Z

|

|

1.1*1000*C

|

80

|

DX51D+Z

|

|

1.2*1000*C

|

80

|

DX51D+Z

|

|

1.2*1050*C

|

150

|

CSB

|

|

1.4*1000*C

|

80

|

DX51D+Z

|

|

SIZE

|

Zinc coating | Material |

|

1.5*1000*C

|

80

|

DX51D+Z

|

|

1.55*1000*C

|

180

|

S280GD+Z

|

|

1.55*1000*C

|

180

|

S350GD+Z

|

|

1.6*1000*C

|

80

|

DX51D+Z

|

|

1.8*1000*C

|

80

|

DX51D+Z

|

|

1.9*1000*C

|

80

|

DX51D+Z

|

|

1.95*1000*C

|

180

|

S350GD

|

|

1.98*1000*C

|

80

|

DX51D+Z

|

|

1.95*1000*C

|

180

|

S320GD+Z

|

|

1.95*1000*C

|

180

|

S280GD+Z

|

|

1.95*1000*C

|

275

|

S350GD+Z

|

|

2.0*1000*C

|

80

|

DX51D+Z

|

|

SIZE

|

Zinc coating | Material |

|

0.36*1250*C

|

80

|

|

|

0.4*1250*C

|

80

|

DX51D+Z

|

|

0.42*1250*C

|

80

|

DX51D+Z

|

|

0.45*1250*C

|

225

|

S280GD+Z

|

|

0.47*1250*C

|

225

|

S280GD+Z

|

|

0.5*1250*C

|

80

|

SGCC

|

|

0.55*1250*C

|

180

|

S280GD+Z

|

|

0.55*1250*C

|

225

|

S280GD+Z

|

|

0.6*1250*C

|

80

|

DX51D+Z

|

|

0.65*1250*C

|

180

|

DX51D+Z

|

|

0.7*1250*C

|

80

|

DX51D+Z

|

|

0.7*1250*C

|

80

|

SGCC

|

|

0.75*1250*C

|

80

|

DX51D+Z

|

|

0.8*1250*C

|

80

|

DX51D+Z

|

|

0.9*1250*C

|

80

|

DX51D+Z

|

|

0.95*1250*C

|

80

|

DX51D+Z

|

|

SIZE

|

Zinc coating | Material |

|

1.0*1250*C

|

80

|

DX51D+Z

|

|

1.15*1250*C

|

80

|

DX51D+Z

|

|

1.1*1250*C

|

80

|

DX51D+Z

|

|

1.2*1250*C

|

80

|

DX51D+Z

|

|

1.35*1250*C

|

80

|

DX51D+Z

|

|

1.4*1250*C

|

80

|

DX51D+Z

|

|

1.5*1250*C

|

80

|

DX51D+Z

|

|

1.55*1250*C

|

80

|

DX51D+Z

|

|

1.6*1250*C

|

120

|

SGCC

|

|

1.6*1250*C

|

80

|

DX51D+Z

|

|

1.8*1250*C

|

80

|

DX51D+Z

|

|

1.85*1250*C

|

90

|

DX51D+Z

|

|

1.95*1250*C

|

80

|

DX51D+Z

|

|

1.75*1250*C

|

80

|

DX51D+Z

|

|

2.0*1250*C

|

80

|

DX51D+Z

|

|

2.0*1250*C

|

120

|

SGCC

|

|

2.5*1250*C

|

80

|

DX51D+Z

|

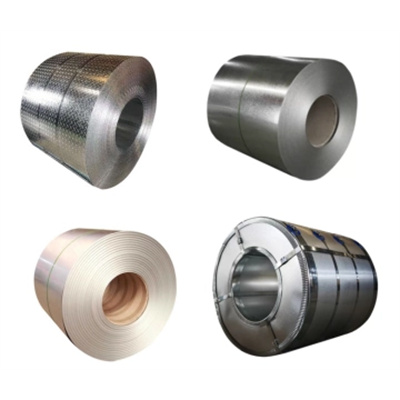

DX51D Galvanized Surface:

(1) the surface state: galvanized sheet due to different treatment methods in the plating process, the surface state is also different, such as ordinary zinc flower, fine zinc flower, flat zinc flower, no zinc flower and phosphating treatment of the surface. The German standard also provides for surface grades.

(2) galvanized sheet should have a good appearance, no harmful defects to the use of the product, such as no plating, holes, rupture and scum, more than plating thickness, abrasion, chromic acid dirt, white rust, etc. Foreign standards are not very clear on the specific appearance defects. When ordering, the specific defects should be specified in the contract.

If you are interested in our products, please feel free to send us an email to inquire.

Our Email: info@gescosteel.com.