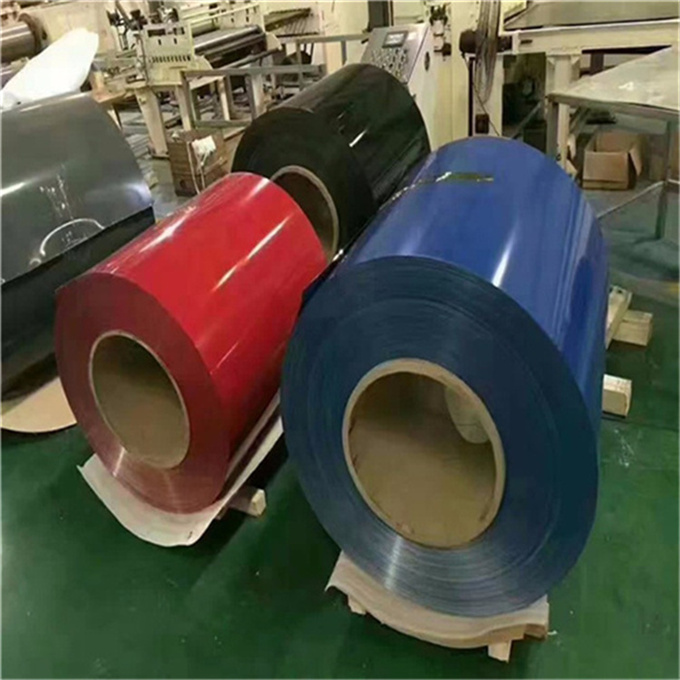

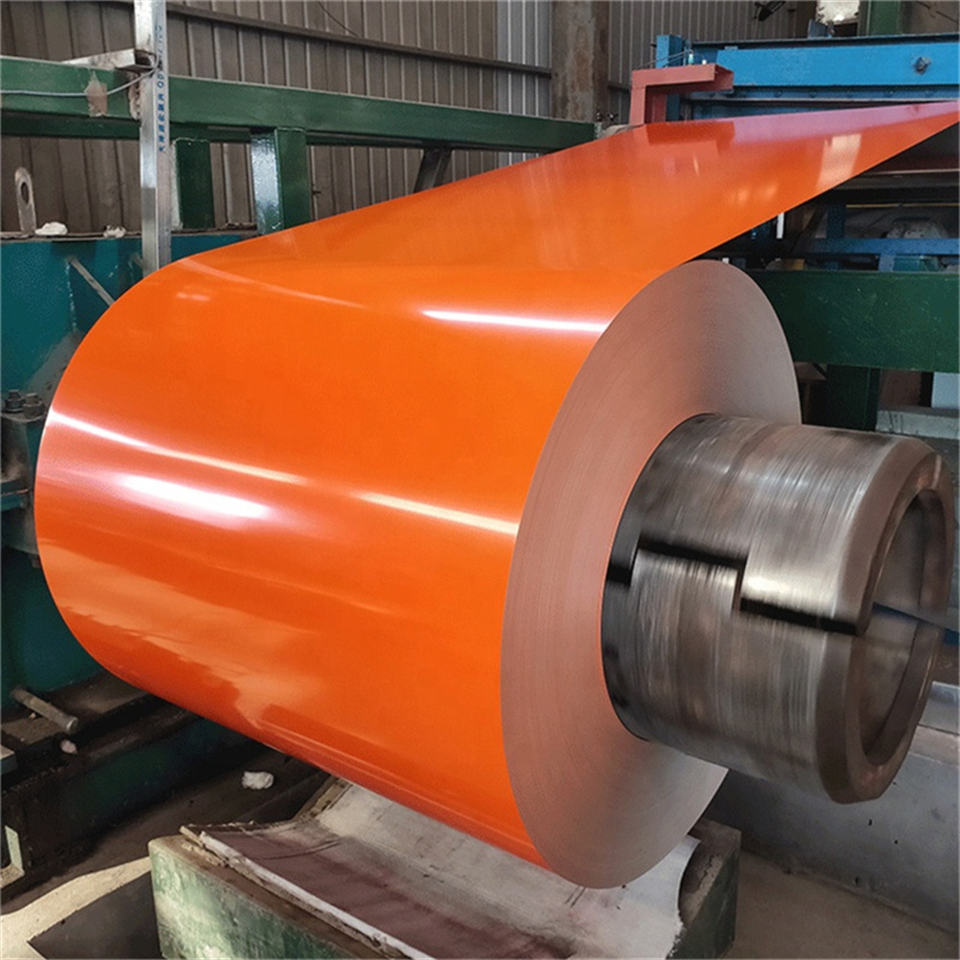

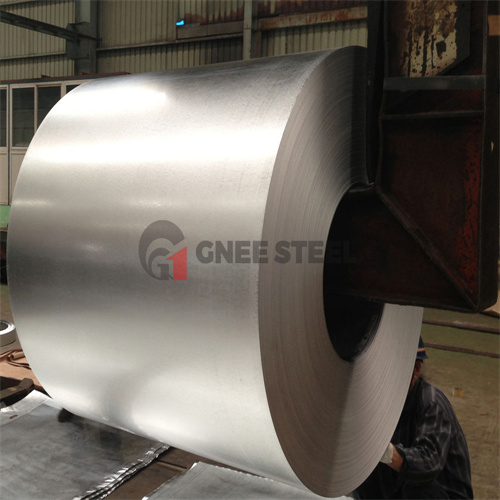

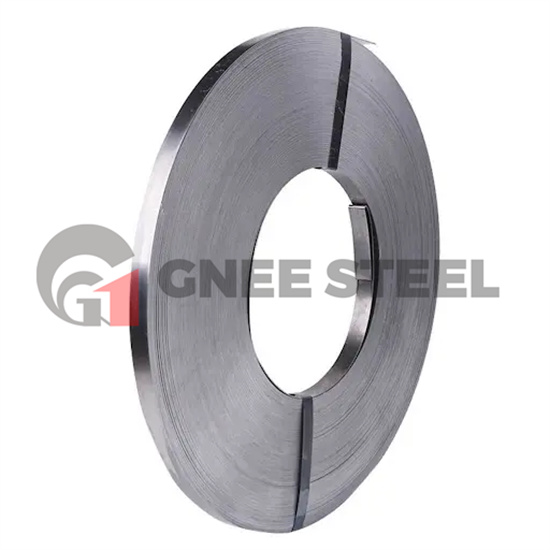

Astm a525 hot dip corrugated galvanized gi steel roofing

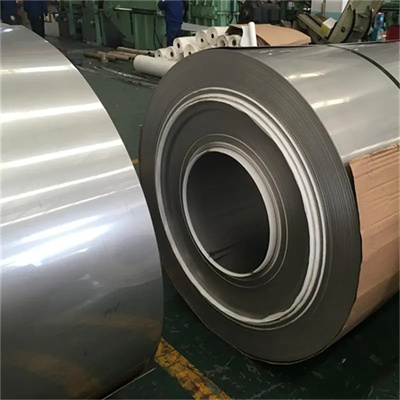

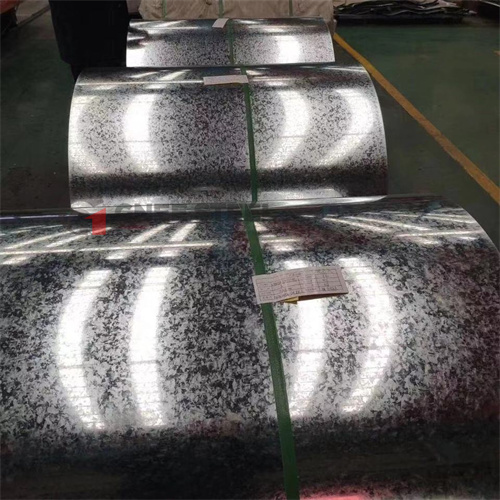

Hot-dip galvanizing is done by pickling the steel parts first, in order to remove the iron oxide from the surface of the steel parts. After pickling, the parts are cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution bath, and then sent to the hot dip plating bath.

|

Product name

|

Astm a525 hot dip corrugated galvanized gi steel roofing | ||

|

Grade

|

CGCC/SGCC/SPCC/DX51D/Q195

|

||

|

Standard

|

GB/T 14978, JISG3321 ,EN10215 , ASTM A792

|

||

|

Thickness

|

0.18MM-1.5MM as customer’s demand

|

||

|

Width

|

914mm-1250mm

|

||

|

Thickness/width tolerance

|

+2/0mm,thickness tolerance :+0.03/-0.03mm (or according to customers’ request). | ||

|

Coil ID

|

508mm/610mm

|

||

|

Technique

|

Cold rolled

|

||

|

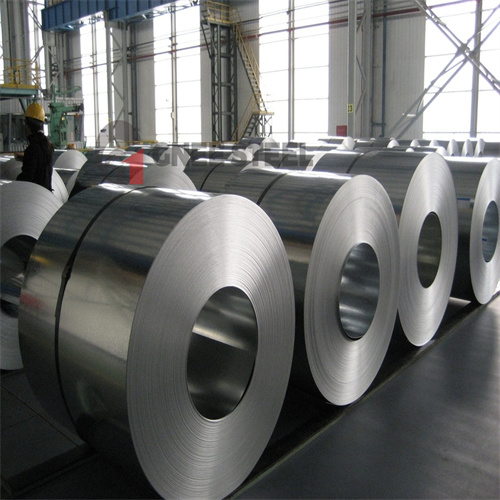

Coil weight

|

2.0MT-8.0MT

|

||

|

Zinc coating

|

40-275g/M2

|

||

Hot-dip galvanizing is one of the most effective means of delaying the environmental corrosion of steel materials. It involves immersing cleaned and activated steel products in a molten zinc solution and coating them with a well-adhered zinc alloy coating through the reaction and diffusion between iron and zinc.If you are interested in our products, please feel free to send us an email to inquire.

Our Email: info@gescosteel.com.