Classification and quality inspection standards of galvanized steel sheets

Galvanized steel plates are divided into ordinary electrolytic plates and fingerprint-resistant electrolytic plates. The fingerprint-resistant board is based on the ordinary electrolytic board and adds a fingerprint-resistant treatment, which can resist sweat. It is generally used on parts that do not undergo any treatment. The grade is SECC-N. Ordinary electrolytic plates are divided into phosphating plates and passivation plates. Phosphating is more commonly used, and the brand name is SECC-P, commonly known as p material. Passivation plates are available with or without oil.

Example:

1. Hot-dip galvanized steel plate (

SGCC) has one advantage over electro-galvanized steel plate (

SECC). SECC’s bending and section are very easy to rust, while SGCC’s rust resistance is much better under the same conditions. High-quality chassis usually use SECC or SGCC galvanized steel plates. The chassis steel plates made of this material are bright in color and have a metallic luster. The advantage of this steel plate is that it has good corrosion resistance.

2. Electro-galvanized steel plate (SECC): uniform gray, mainly imported, resistant to fingerprints, has excellent corrosion resistance, and maintains the processability of cold-rolled plates. Usage: Home appliances, computer case casings and some door panels and panels.

Divided by zinc: The size of the zinc flowers and the thickness of the zinc layer can indicate the quality of galvanizing. The smaller and thicker the better. Manufacturers can also add fingerprint-resistant processing. In addition, it can be distinguished by its coating. For example, Z12 means that the total coating amount on both sides is 120g/mm.

The

hot-dip galvanized steel sheets produced by Chinese manufacturers are mainly used in the building materials, light industry, agriculture, transportation and other industries. Due to limitations of existing hot-dip galvanizing equipment conditions, process technology and original plate performance, very few galvanized sheets are actually produced for use in the automobile manufacturing industry.

Features of galvanized steel sheets:

Galvanizing can effectively prevent steel corrosion and extend its service life. Galvanized thin steel sheet (thickness 0.4~1.2mm) is also called galvanized iron sheet, commonly known as tinplate. Galvanized steel sheets are widely used in construction, vehicles, home appliances, daily necessities and other industries.

Quality inspection standards:

The quality requirements for high-quality galvanized sheets include specifications, dimensions, surface, galvanizing amount, chemical composition, plate shape, machine function and packaging.

1. Package

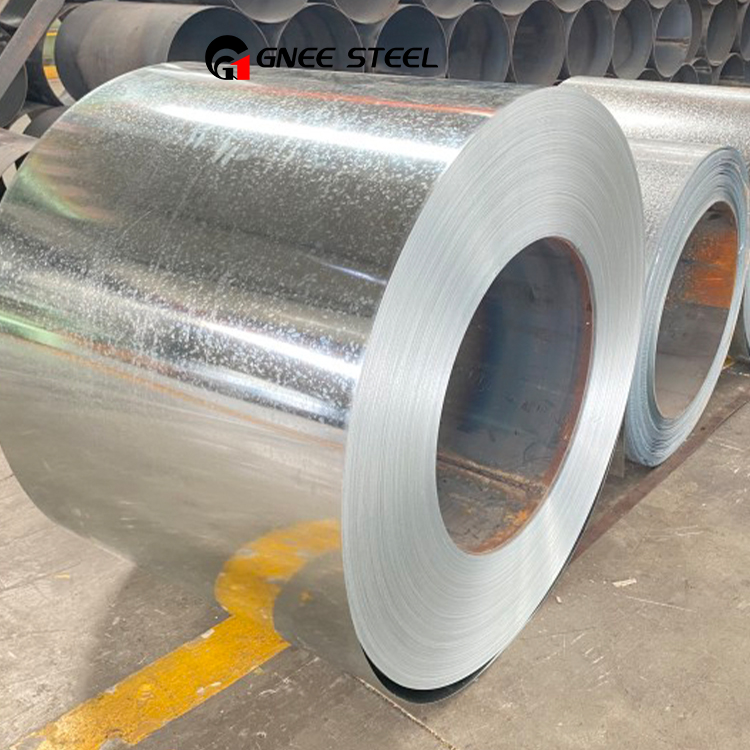

It is divided into two types: galvanized sheet cut into fixed lengths and galvanized sheet packaging in coils. It is generally packed in iron sheets, lined with moisture-proof paper, and tied with an iron waist on the outside. The fastening is firm to prevent the galvanized sheets inside from rubbing against each other.

2. Standard sizes

Relevant product standards (as described below) all list the recommended standard thickness, length and width of galvanized sheets and their allowable defects. In addition, the width and length of the board and the width of the roll can also be determined according to user requirements.

3. surface

Surface conditions: Due to different treatment methods in the coating process, the surface conditions of galvanized sheets are also different, such as ordinary zinc flowers, fine zinc flowers, flat zinc flowers, no zinc flowers, and phosphating treated surfaces. Galvanized sheets and galvanized coils cut to a fixed length must not have shortcomings that affect their use, but coiled sheets are allowed to have less deformed parts such as welding parts.

4. Galvanizing amount

Galvanizing quantity scale value: Measuring the galvanizing quantity is a widely adopted method to determine the zinc layer thickness of galvanized sheets. There are two types: the same amount of galvanizing on both sides (i.e. equal thickness galvanizing) and the unequal amount of galvanizing on both sides (i.e. differential thickness galvanizing). The unit of galvanizing amount is g/m2.

5. Machine function

(1) Tensile test: Generally speaking, only galvanized sheets for structural, tensile and deep drawing purposes have tensile performance requirements.

(2) Bending test: It is an important item to measure the process performance of thin plates. However, countries around the world have different requirements for various types of galvanized sheets. It is generally required that after the galvanized sheet is bent 180°, the zinc layer must not leave the outer coating, and the base of the sheet must not have cracks or breaks.

6.chemical composition

The requirements for the chemical composition of galvanized substrates vary from country to country. If Japan has this requirement, the United States does not. Generally no product inspection is done.

7. plate shape

There are two indicators for weighing the quality of board shape, namely straightness and sickle curve. There are certain regulations on the maximum allowable values of plate flatness and sickle bend.