Do you understand how to process galvanizing equipment?

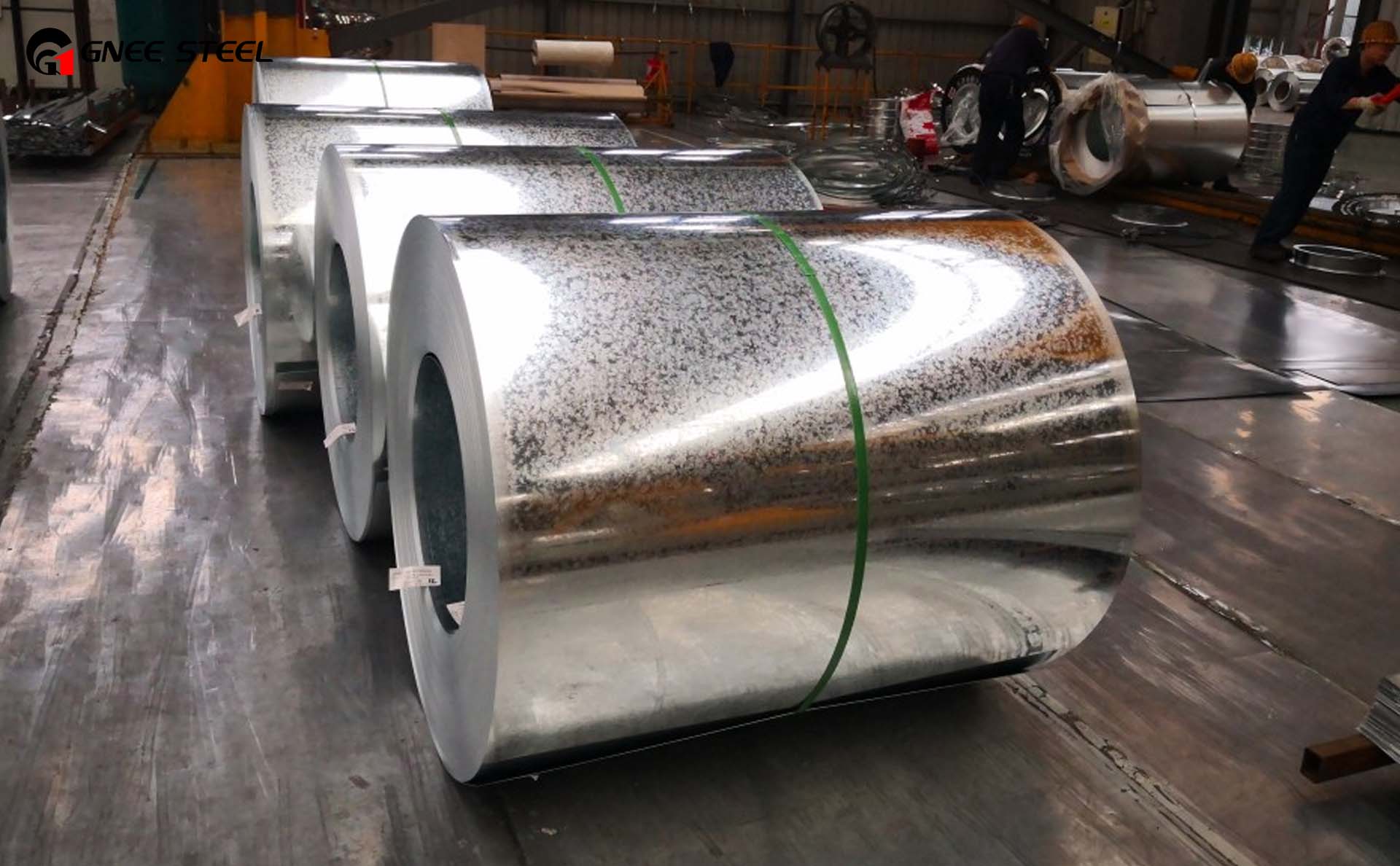

According to the current hot dip galvanizing process to maintain the production of hot dip galvanizing industrial equipment and production and processing, is currently galvanizing equipment production and manufacturing industry commonly used and commodity circulation of a production and processing aspects of the process skills. Today we will explain the key production processes involved in the production of galvanizing equipment.

Galvanizing equipment is able to use manual services to carry out the surface of the galvanizing equipment to solve the rust and paint solution.

In the case of hot dip galvanizing, different acid-resistant machines and equipment are used for lifting different workpieces.

Oil stains on the surface of the workpiece can be degreased by alkaline washing. After alkali washing, the workpiece can be immersed in water to dilute the residual caustic soda solution on the surface of the workpiece. The purpose is to remove iron oxide and surface rust from the surface of the workpiece.

Immersed in water can help pickling passivation after the machine equipment workpiece, solution wash residual acid solution, can be better to prevent excessive acid and ferrous ions to help carbon solvent. Carbonated solvents to help plating to solve the surface of the workpiece, to avoid air oxidation of the surface of the workpiece air drying again, dissolve the molten zinc liquid adhering to the surface of the workpiece zinc oxide layer, so that the steel conventional and hot-dip galvanized layer of the middle of the combination.